Industrial facilities rely on various air-moving devices to support ventilation, drying, combustion, and material handling processes. Among these, industrial blowers, fans, and compressors are frequently used, yet the distinctions among them are often misunderstood. Although they all move air or gas, their design, pressure output, and intended applications are quite different. Understanding how these systems differ helps engineers, plant operators, and maintenance teams choose the most efficient and cost-effective equipment for each application.

Understanding the Basics of Air Movement

Air movement devices operate based on the same fundamental principle: they impart energy to air or gas to make it flow from one location to another. The difference lies in the amount of pressure they generate and the way they deliver the airflow.

- Fans move large volumes of air at low pressure. They are ideal for ventilation or cooling where air resistance is minimal.

- Blowers provide moderate pressure and are used where air must be moved through ducts, filters, or equipment that create resistance.

- Compressors produce high pressure and are used to compress air or gas for storage or to power pneumatic systems.

Each serves a unique role in industrial operations, and selecting the right one depends on the required pressure, volume, and end use.

Defining an Industrial Fan

Industrial fans are devices designed to move a large quantity of air at relatively low pressure. They typically generate a pressure increase of less than 1.1 times atmospheric pressure. The air leaving the fan is only slightly pressurized compared to the air entering it.

Fans work primarily through the action of rotating blades connected to an impeller, which transfers mechanical energy from a motor to the air. The blades create a continuous flow that helps circulate air or remove heat, dust, or fumes.

Industrial fans are found in ventilation systems, cooling towers, ovens, HVAC units, and manufacturing environments where air renewal or temperature control is needed.

There are two main types of fans used in industry:

- Axial fans – These move air parallel to the shaft of the blades, much like a household fan. They are efficient for high-volume, low-pressure airflow.

- Centrifugal fans – These move air radially by using a spinning impeller to increase velocity and direct air outward. They can handle higher resistance and are suitable for ducted systems.

Fans are chosen primarily for applications that need high airflow and low pressure. They are also valued for their simplicity, relatively low energy use, and ease of maintenance.

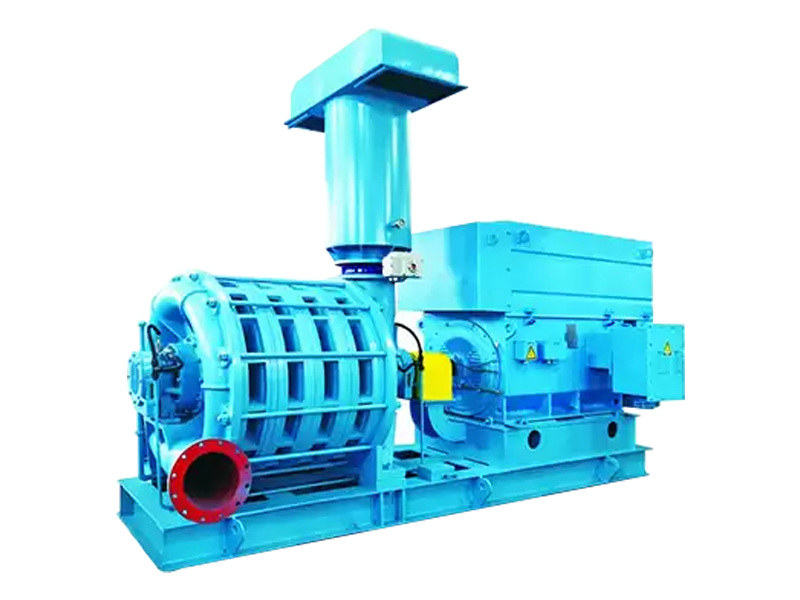

Defining an Industrial Blower

An industrial blower bridges the gap between a fan and a compressor. It provides higher pressure than a fan but lower pressure than a compressor. In technical terms, a blower typically delivers a pressure ratio between 1.1 and 2.0 times atmospheric pressure.

Blowers are designed to move air or gas through systems where moderate resistance exists, such as long ducts, filters, or process equipment. The goal is to maintain steady airflow against this resistance.

The most common types of blowers include:

- Centrifugal blowers – These use impellers with multiple blades to accelerate air outward from the center and convert velocity into pressure. They are suitable for applications such as furnace combustion, wastewater aeration, and dust collection.

- Positive displacement blowers – These trap a fixed volume of air and push it through the outlet. They can deliver a constant flow regardless of system pressure and are often used in pneumatic conveying, wastewater treatment, and vacuum applications.

Blowers are versatile and can handle clean, dusty, or slightly contaminated air. Their design ensures a steady and controllable airflow, which is critical in processes where pressure stability affects product quality or system efficiency.

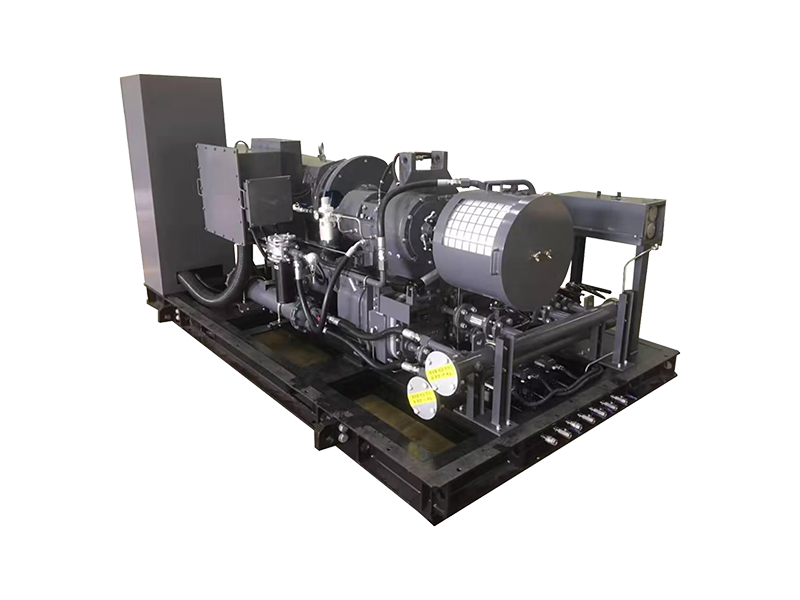

Defining an Industrial Compressor

A compressor takes air or gas and compresses it to much higher pressures, often several times atmospheric pressure. It is designed not just to move air but to increase its density by reducing its volume. The resulting compressed air stores energy that can be used for mechanical work, such as operating pneumatic tools, valves, or actuators.

Compressors are divided into two main categories:

- Positive displacement compressors – These compress air by reducing the volume of a sealed chamber. Common types include piston, screw, and vane compressors.

- Dynamic compressors – These use rapidly rotating impellers to impart velocity and then convert it into pressure, as seen in centrifugal and axial compressors.

Because compressors are designed for much higher pressure output than blowers or fans, they require stronger materials, tighter seals, and more energy. Their operation is typically continuous in industrial settings where consistent air pressure is critical.

Pressure and Flow Differences

The easiest way to distinguish among fans, blowers, and compressors is by comparing their pressure ranges.

- Fans – Generate a pressure ratio up to 1.1

- Blowers – Generate a pressure ratio between 1.1 and 2.0

- Compressors – Generate a pressure ratio greater than 2.0

This difference in pressure capability affects the type of flow they create. Fans produce a large volume of air with low pressure, blowers provide moderate air volume with medium pressure, and compressors generate high pressure with relatively low air volume.

Energy Consumption and Efficiency

Energy consumption rises as the required pressure increases. Fans are the most energy-efficient devices because they operate at low pressure. Blowers consume more energy since they must overcome greater system resistance, while compressors are the most energy-intensive because compressing air to high pressures requires significant power.

To improve efficiency, modern systems often integrate variable frequency drives or control systems to match airflow output to process demands. Selecting the right equipment for the required pressure range prevents wasted energy and unnecessary operational costs.

Construction and Design Variations

Although the basic principle of imparting kinetic energy to air is similar across all three devices, their design reflects their intended use.

- Fans have wide blades designed for large airflow and low resistance. Their casings are relatively open to allow high-volume flow.

- Blowers have more complex housings and impellers that allow them to generate and maintain medium pressure. Some include multi-stage designs for higher pressure output.

- Compressors have tightly sealed chambers or impellers with minimal air leakage. They are built from high-strength materials to withstand elevated pressures and temperatures.

The design differences directly influence not only the pressure generated but also the type of maintenance required.

Applications in Industry

Each device serves a specific function across a range of industrial environments.

- Fans are used for general ventilation, cooling, drying, and air circulation. They are essential in HVAC systems, manufacturing workshops, and exhaust setups.

- Blowers are used in pneumatic conveying, combustion air supply, vacuum systems, wastewater aeration, and dust collection. They are often found where controlled airflow at moderate pressure is required.

- Compressors are used for high-pressure air supply, instrument air systems, gas transport, refrigeration, and powering pneumatic machinery.

In some plants, all three systems operate together, with fans maintaining airflow, blowers providing process pressure, and compressors handling power-driven pneumatic operations.

Maintenance Considerations

Proper maintenance is essential for reliable operation and energy efficiency.

- Fans require periodic cleaning of blades, inspection of bearings, and balancing to prevent vibration.

- Blowers need lubrication of moving parts, inspection of seals, and monitoring of air filters and belts.

- Compressors demand regular oil changes, inspection of pressure relief valves, and monitoring of temperature and vibration.

Preventive maintenance helps extend the life of each device and reduces unplanned downtime, which can be costly in continuous production environments.

Selecting the Right Equipment

Choosing between a fan, blower, or compressor depends on the process requirements. The selection criteria include:

- Required pressure and airflow – The higher the pressure needed, the more likely a blower or compressor will be necessary.

- System resistance – If the system includes filters, ducts, or long pipelines, a blower may be more suitable than a fan.

- Energy efficiency – Using a compressor where only a blower is needed wastes energy. Matching the device to its intended purpose is key.

- Air quality – Clean air systems may use fans, while contaminated or particulate-laden air often requires blowers with protective housings.

- Maintenance and cost – Fans are the least costly and easiest to maintain, followed by blowers, then compressors.

Proper evaluation of these factors ensures optimal performance and lower operating costs.

The Overlap in Applications

In some industrial settings, the distinction between these devices may blur. For instance, a high-pressure fan might perform functions similar to a low-end blower, and certain low-pressure compressors might operate in applications similar to those of blowers. However, understanding their pressure ranges and intended functions prevents misapplication that could lead to energy inefficiency or equipment damage.

Conclusion

Although industrial blowers, fans, and compressors all move air or gas, their design, purpose, and pressure capabilities set them apart. Fans move large amounts of air at low pressure, blowers generate moderate pressure for process systems, and compressors produce high-pressure air for energy storage or mechanical work.

Selecting the right equipment is not simply a matter of choosing the most powerful device. It involves understanding system resistance, pressure needs, energy consumption, and maintenance demands. By knowing how these systems differ, industries can optimize performance, reduce operating costs, and maintain a safe and efficient working environment.

русский

русский Español

Español عربى

عربى