If you would like to learn more about our products, please feel free to contact us and we will do our to assist you.

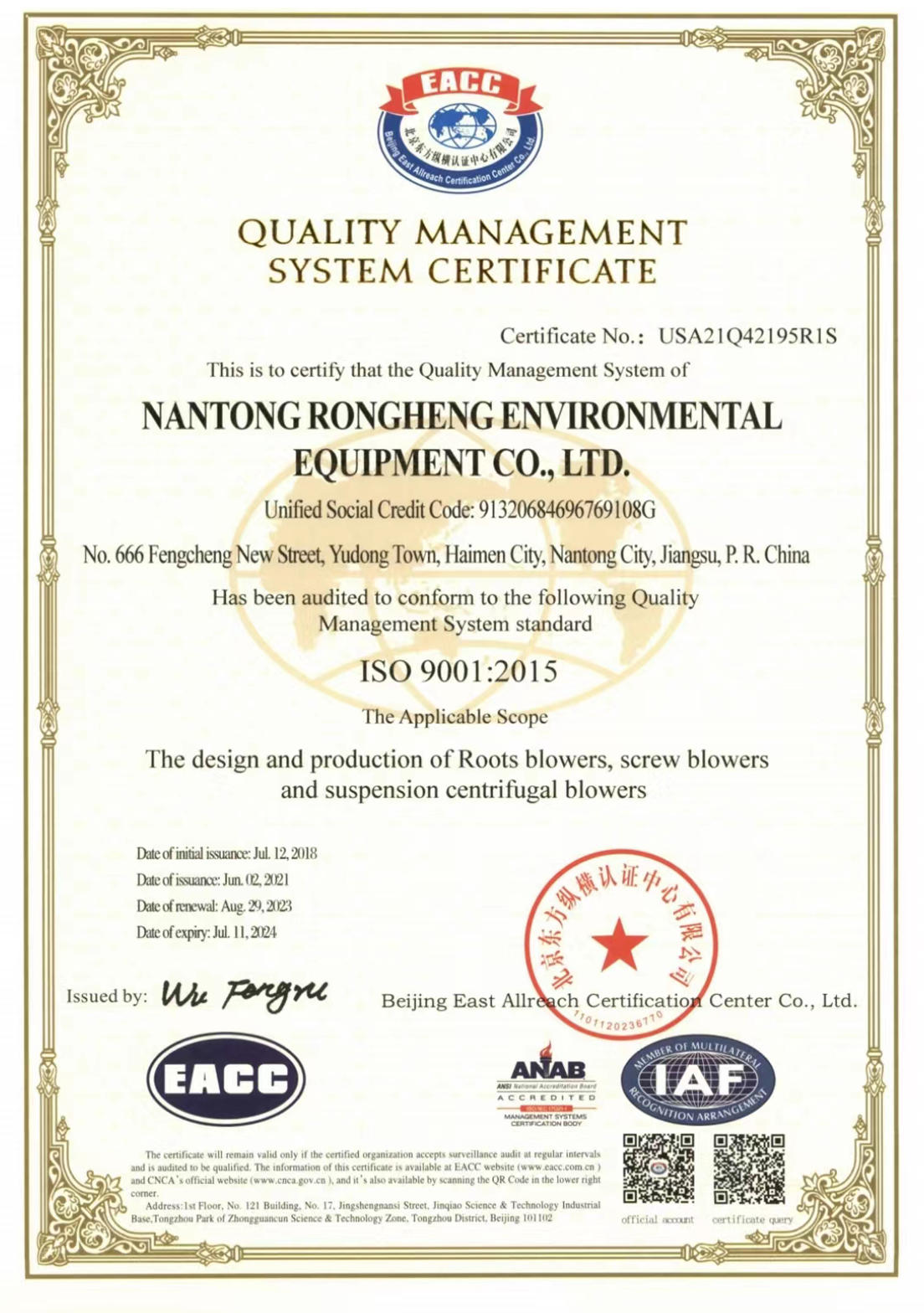

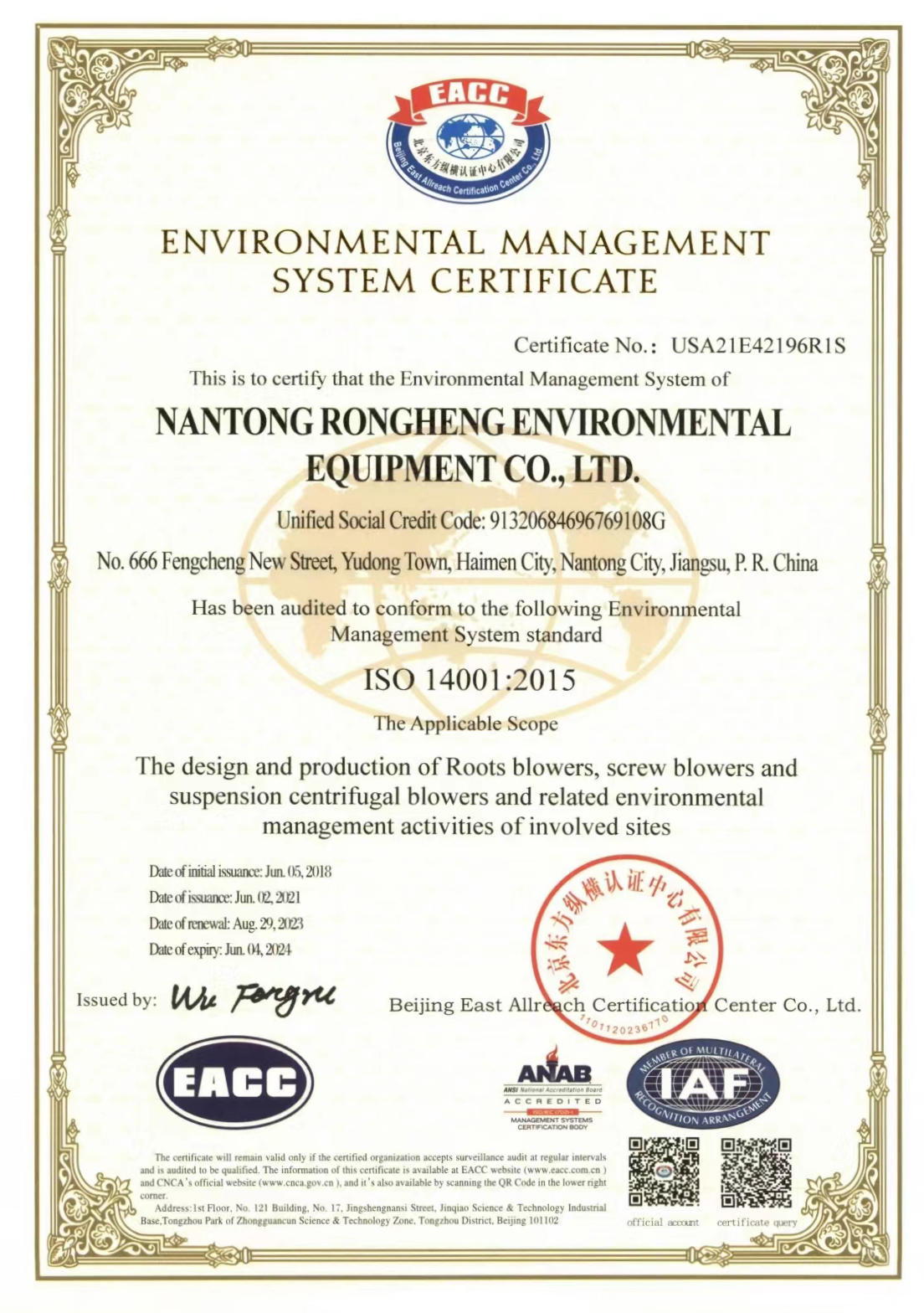

Nantong Rongheng Environmental Protection Equipment Co., Ltd. is a professional company engaged in the development, manufacturing, sales and service of various types of blowers, vacuum pumps and other products. OEM/ODM OIL-free Screw Blowers Manufacturers and OIL-free Screw Blowers Factory in China. Products cover general-purpose three-blade roots blowers, explosion-proof three-blade roots blowers, anti-corrosion three-blade roots blowers, high temperature and high-pressure three-blade roots blowers and units, three-blade roots vacuum pumps and units, rotary fans, Various safety valves, muffler devices, etc. We have a strong R&D team,and we can develop and produce products according to the drawings or samples the customers offered. Provide professional OEM and ODM service to meet your needs. OIL-free Screw Blowers Custom. Having sufficient manufacturing capacity and scale to meet market demand. This includes the number of production equipment, the layout and management capabilities of the production line, as well as the control of the production cycle.

-

1890

Was founded in

-

133+

Industry experience

-

xxx

Patent Certificate

-

xx+

Automatic production line

If you would like to learn more about our products, please feel free to contact us and we will do our to assist you.

-

In the realm of industrial material handling, pneumatic conveying systems have gained significant prominence due to thei...

READ MORE -

1. Introduction Roots Rotary Lobe Blowers, named after their inventors Philander Higley Roots and Frances Marion Roots...

READ MORE -

Multistage centrifugal blowers are crucial rotating machines in various industrial and commercial applications. They are...

READ MORE -

I. Introduction: Start the Journey of Exploring Roots Blowers On the grand stage of industry, Roots blowers are like a l...

READ MORE

When it comes to selecting a blower system for industrial or commercial applications, factors such as noise levels and operational smoothness play a crucial role in decision-making.

1. Noise Levels:

Oil-Free Screw Blowers:

Oil-free screw blowers are renowned for their relatively quiet operation compared to oil-injected blowers. This advantage stems from the design principle that eliminates the need for oil-lubricated gears and bearings. By doing so, the sources of mechanical noise are significantly reduced.

Furthermore, the absence of oil in the compression chamber minimizes the chances of oil mist or droplets escaping into the surrounding environment, which can contribute to elevated noise levels in oil-injected blowers. Modern advancements in oil-free screw blower technology often integrate sound-dampening features and sophisticated engineering techniques, further mitigating noise emissions.

In environments where noise pollution is a concern, such as laboratories, hospitals, and office buildings, oil-free screw blowers provide a quieter and more conducive working atmosphere.

Oil-Injected Blowers:

On the other hand, oil-injected blowers typically exhibit higher noise levels compared to their oil-free counterparts. The presence of oil within the blower's mechanisms, particularly in gears and bearings, can generate additional noise during operation. Additionally, oil mist or droplets escaping from the blower can contribute to an increase in ambient noise levels.

While efforts can be made to reduce noise through sound insulation and enclosure designs, oil-injected blowers inherently face challenges in achieving the same level of noise reduction as oil-free screw blowers.

2. Operational Smoothness:

Oil-free screw blowers:

Operational smoothness is another area where oil-free screw blowers excel. The absence of oil in the compression chamber reduces friction and wear on internal components, resulting in a smoother and more consistent airflow. This smoother operation not only enhances efficiency but also contributes to reduced vibration levels.

The stability of the compression process in oil-free screw blowers leads to a more reliable and predictable performance, minimizing fluctuations in output and ensuring consistent results. This operational smoothness translates into lower maintenance requirements and extended equipment lifespan.

Oil-Injected Blowers:

In contrast, oil-injected blowers may experience operational challenges related to oil contamination and wear on moving parts. The presence of oil can lead to variances in airflow and pressure, impacting the blower's performance and requiring more frequent maintenance interventions.

Moreover, the lubrication oil in oil-injected blowers can deteriorate over time, leading to increased friction, heat generation, and potential mechanical issues. These factors contribute to a less smooth and stable operation compared to oil-free screw blowers.

русский

русский Español

Español عربى

عربى