1. Introduction

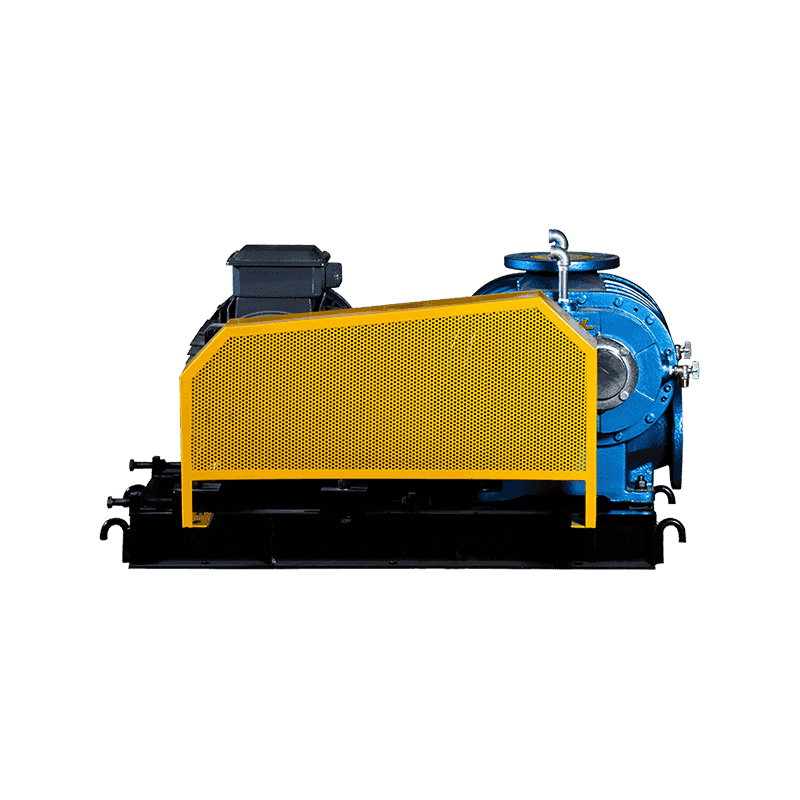

Roots Rotary Lobe Blowers, named after their inventors Philander Higley Roots and Frances Marion Roots who patented the design in 1860, are a crucial type of positive - displacement blower in various industrial applications. They are designed to move air or gas at a relatively constant volume regardless of the pressure changes in the system, making them highly reliable for many processes.

2. Working Principle

2.1 Basic Structure

Roots Rotary Lobe Blowers typically consist of two or more rotors (usually twin - lobe or tri - lobe) mounted on parallel shafts within a casing. In a twin - lobe compressor, each rotor has two lobes, resulting in a total of four lobes per compressor. In a tri - lobe machine, each rotor has three lobes, giving six lobes per compressor. Twin - lobe (bi - lobe) machines are commonly used for process gas applications, while tri - lobe machines offer certain advantages in terms of smoother operation and reduced pulsation.

2.2 Operational Process

Intake Phase: As the rotors rotate, a volume of air or gas is trapped between the lobes and the casing at the inlet side of the blower. The rotation of the rotors creates a low - pressure area at the inlet, drawing in the fluid.

Transport Phase: The trapped volume of fluid is then carried around the circumference of the rotor housing as the rotors continue to turn. The rotors rotate in opposite directions, and the meshing of the lobes ensures a seal between the inlet and outlet sides, preventing backflow.

Discharge Phase: When the lobes reach the outlet side, the trapped fluid is compressed to the system pressure at the outlet and expelled. Small but precisely designed clearances between the lobes and the casing allow for operation without the need for internal lubrication in the air or gas - handling part, reducing the risk of contamination in the fluid being processed. Timing gears are used to control the relative position of the rotors, ensuring smooth and synchronized operation.

3. Performance Characteristics

3.1 Flow Rate

Roots Rotary Lobe Blowers can achieve a wide range of flow rates. Smaller models may have flow rates suitable for applications like small - scale pneumatic conveying or local ventilation, while larger industrial - grade models can handle extremely high flow rates, reaching up to 120,000 m³/hr (70,000 cfm) in some cases. The flow rate is relatively stable over a wide range of operating conditions, as long as the rotational speed of the rotors remains constant. This makes them ideal for applications where a consistent volume of air or gas is required, such as in pneumatic conveying systems where materials need to be transported at a steady rate.

3.2 Pressure and Vacuum Capabilities

Positive Pressure: These blowers can generate positive pressures up to a certain limit. For example, some models can reach pressures of up to 35 psig. They are used in applications like combustion air supply in industrial furnaces, where a specific positive pressure is needed to ensure efficient fuel - air mixing and combustion.

Vacuum Generation: Roots Blowers can also function as vacuum boosters, capable of creating vacuums down to 28” Hg or even higher in some specialized high - vacuum models. In applications such as vacuum filtration in the chemical industry or in the drying of certain products, the ability to generate a reliable vacuum is crucial.

3.3 Efficiency

While not as energy - efficient as some centrifugal blowers in certain high - flow, low - pressure applications, Roots Rotary Lobe Blowers offer good efficiency in their typical operating range of medium - pressure and variable - flow applications. Their positive - displacement nature ensures that they can maintain a consistent volume flow even against varying system pressures, which can be more energy - efficient in applications where flow stability is a priority. Additionally, advancements in design, such as improved lobe profiles and reduced internal clearances, have helped to increase their overall efficiency over the years.

3.4 Noise and Vibration

Traditional Roots Blowers were known for relatively high noise and vibration levels due to the meshing of the lobes and the pulsating nature of the fluid flow. However, modern designs, especially those incorporating innovative features like WHISPAIR™ technology, have significantly reduced noise and vibration. These technologies work by optimizing the lobe shape, improving the balance of the rotors, and using better - quality materials. For example, acoustic enclosures can be added to further reduce noise, providing up to 22 dBA free - field attenuation. This makes them more suitable for applications in noise - sensitive environments, such as in food and beverage processing plants or near residential areas.

4. Applications

4.1 Industrial Applications

Pneumatic Conveying: Roots Rotary Lobe Blowers are widely used in pneumatic conveying systems to transport dry bulk materials such as grains, powders, and pellets. The consistent flow rate and ability to handle different pressures make them suitable for moving materials over long distances and through complex piping systems. For example, in the food industry, they are used to convey flour, sugar, and other ingredients between different processing stages.

Chemical and Gas Processing: In the chemical industry, these blowers are used for applications like gas circulation, agitation in reactors, and in the processing of various gases such as nitrogen, hydrogen, and hydrocarbons. They can handle corrosive and reactive gases when made with appropriate materials. For instance, in a petrochemical plant, Roots Blowers may be used to circulate gases in a catalytic reactor to ensure proper mixing and reaction rates.

Mining and Metallurgy: In mining operations, they are used for tasks such as pneumatic drill air supply, ventilation in underground mines, and in the processing of ores. In metallurgy, they play a role in processes like steel degassing, where high - vacuum Roots Blowers are used to remove impurities from molten steel.

4.2 Environmental Applications

Water and Wastewater Treatment: In water treatment plants, Roots Blowers are used for aeration purposes. They supply oxygen to the water, which is essential for the growth of aerobic bacteria that break down organic matter in wastewater. They are also used for filter backwashing, where the high - pressure air helps to clean the filters by dislodging trapped particles. In sewage treatment plants, the blowers ensure proper aeration in the activated sludge process, which is crucial for effective wastewater treatment.

Environmental Pollution Control: They can be used in systems for controlling air pollution, such as in the collection and transportation of dust and fumes. For example, in a cement factory, Roots Blowers may be used to convey dust - laden air to a dust - collection system, preventing the release of harmful particulate matter into the atmosphere.

4.3 Other Applications

Food and Beverage Industry: In this industry, Roots Blowers are used for tasks such as bottle blowing in the production of plastic bottles, pneumatic conveying of food products, and in the packaging process. They are also used in the fermentation process of beverages like beer and wine, where they provide the necessary air for yeast growth and fermentation.

Power Generation: In power plants, they are used for combustion air supply in boilers, ensuring efficient fuel combustion and higher power generation efficiency. They can also be used in the cleaning of power plant equipment, such as in the backwashing of air filters in gas - turbine power plants.

5. Comparison with Other Blower Types

| Blower Type | Principle | Flow Rate Characteristics | Pressure Capability | Efficiency | Noise Level | Applications |

| Roots Rotary Lobe Blower | Positive - displacement; traps and transports fluid between lobes | Relatively constant flow rate regardless of pressure changes | Can achieve medium to high positive pressures and vacuums | Good in medium - pressure, variable - flow applications | Historically high, but modern designs have reduced noise | Pneumatic conveying, chemical processing, water treatment, etc. |

| Centrifugal Blower | Uses centrifugal force to accelerate and move fluid | Flow rate can vary with pressure changes; higher flow rates at lower pressures | Generally better for low - pressure, high - flow applications | High efficiency in high - flow, low - pressure scenarios | Relatively lower noise in some cases | HVAC systems, general ventilation |

| Axial Blower | Moves fluid parallel to the axis of rotation | High flow rates, but pressure rise is relatively small | Low - pressure applications | Efficient for high - volume, low - pressure air movement | Can be noisy, especially at high speeds | Cooling towers, tunnel ventilation |

6. Maintenance and Troubleshooting

6.1 Regular Maintenance

Lubrication: Although the air - handling part is typically oil - free, the bearings and timing gears of Roots Rotary Lobe Blowers require regular lubrication. Using the correct type of lubricant and following the manufacturer's recommended lubrication intervals is crucial to ensure smooth operation and prevent premature wear.

Inspection of Belts and Couplings: If the blower is belt - driven, the belts should be checked regularly for signs of wear, tension, and alignment. Couplings, if present, should also be inspected for proper connection and any signs of damage.

Air Filter Maintenance: The air filter, which protects the blower from dust and other contaminants, needs to be cleaned or replaced regularly. A clogged air filter can increase the pressure drop, reduce the blower's efficiency, and potentially cause damage to the rotors.

6.2 Troubleshooting Common Issues

Low Flow Rate: This can be caused by a variety of factors, such as a clogged air filter, leaks in the piping system, or worn - out rotors. Inspecting and cleaning the air filter, checking for leaks in the system, and examining the condition of the rotors are common troubleshooting steps.

High Noise or Vibration: Excessive noise or vibration may indicate problems such as misaligned rotors, worn - out bearings, or damaged timing gears. Checking the alignment of the rotors, replacing worn - out bearings, and inspecting and replacing damaged timing gears can help resolve these issues.

Overheating: Overheating can be due to insufficient cooling (if the blower is air - or water - cooled), high - pressure operation beyond the blower's rated capacity, or mechanical problems such as excessive friction. Ensuring proper cooling, checking the operating pressure, and addressing any mechanical issues are necessary to solve overheating problems.

7. Future Developments

Energy - Efficiency Improvements: With the increasing focus on energy conservation and sustainability, future developments in Roots Rotary Lobe Blowers are likely to focus on further improving their energy efficiency. This may involve the use of advanced materials, more efficient lobe designs, and better - optimized internal clearances to reduce energy losses.

Smart Technology Integration: The integration of smart sensors and controls is another area of development. Smart blowers can monitor their own performance, such as flow rate, pressure, temperature, and vibration, and adjust their operation accordingly. This can lead to better - optimized performance, reduced maintenance needs, and increased overall reliability.

Customization for Special Applications: As industries continue to develop and new applications emerge, there will be a growing demand for customized Roots Blowers. Manufacturers will likely focus on developing blowers tailored to specific industry needs, such as those with enhanced corrosion resistance for use in harsh chemical environments or those with special noise - reduction features for use in sensitive areas.

русский

русский Español

Español عربى

عربى