If you would like to learn more about our products, please feel free to contact us and we will do our to assist you.

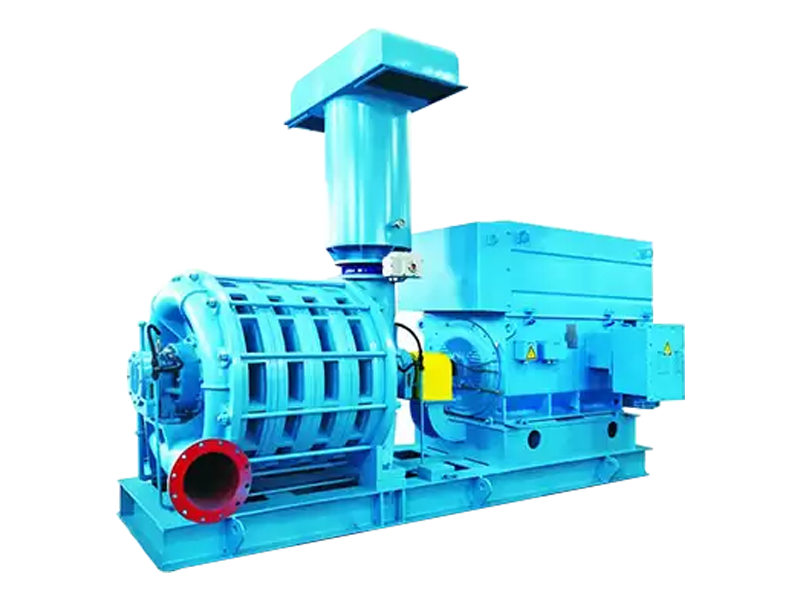

Nantong Rongheng Environmental Protection Equipment Co., Ltd. is a professional company engaged in the development, manufacturing, sales and service of various types of blowers, vacuum pumps and other products. OEM/ODM Multistage Centrifugal Blowers Manufacturers and Centrifugal Industrial Blowers Factory in China. Products cover general-purpose three-blade roots blowers, explosion-proof three-blade roots blowers, anti-corrosion three-blade roots blowers, high temperature and high-pressure three-blade roots blowers and units, three-blade roots vacuum pumps and units, rotary fans, Various safety valves, muffler devices, etc. We have a strong R&D team,and we can develop and produce products according to the drawings or samples the customers offered. Provide professional OEM and ODM service to meet your needs. Custom Industrial Centrifugal Blowers & Fans. Having sufficient manufacturing capacity and scale to meet market demand. This includes the number of production equipment, the layout and management capabilities of the production line, as well as the control of the production cycle.

-

1890

Was founded in

-

133+

Industry experience

-

xxx

Patent Certificate

-

xx+

Automatic production line

If you would like to learn more about our products, please feel free to contact us and we will do our to assist you.

-

In the ever-evolving landscape of industrial and environmental technology, maglev turbo blower have emerged as a cutting...

READ MORE -

A low flow inlet multi stage centrifugal blower is typically used in applications where low flow rates but high pressure...

READ MORE -

How do temperature and environmental conditions impact the performance of Roots rotary lobe blowers?

Roots rotary lobe blowers are widely used in the industry for their efficient and reliable gas delivery capabilities. Ho...

READ MORE -

In the industrial world, Roots rotary lobe blowers are highly valued for their efficiency and durability. However, when ...

READ MORE

A multistage centrifugal blower typically consists of several key components that work together to facilitate the movement of air or gas.

Impeller: The impeller is a rotating component with curved blades or vanes that accelerate the air or gas as it passes through the blower. It is typically mounted on a shaft and is responsible for generating the centrifugal force necessary for the blower's operation.

Housing or Casing: The housing or casing surrounds the impeller and provides a passage for the airflow. It is designed to guide the air or gas from the inlet to the outlet while maintaining the desired pressure and flow characteristics.

Inlet and Outlet Connections: These are the entry and exit points for the air or gas into and out of the blower. The inlet connection allows ambient air or gas to enter the blower, while the outlet connection directs the pressurized air or gas towards the desired application or system.

Shaft: The shaft connects the impeller to the motor or drive system. It transmits the rotational motion from the motor to the impeller, enabling the generation of centrifugal force.

Bearings: Bearings support the shaft and help reduce friction during operation. They are crucial for maintaining smooth rotation and stability of the impeller within the blower.

Drive System: The drive system consists of components such as a motor, gearbox, belts, pulleys, or direct drive mechanisms. It provides the power necessary to rotate the impeller and drive the blower's operation.

Seals: Seals are used to prevent air or gas leakage between moving parts, such as the impeller and housing, or at the shaft entry points. Proper sealing is essential for maintaining efficiency and preventing contamination.

Cooling System: In some cases, multistage centrifugal blower may include a cooling system to manage the temperature of internal components and prevent overheating during prolonged operation.

Control and Monitoring Devices: These devices can include sensors, gauges, valves, and control panels that monitor and regulate parameters such as airflow, pressure, temperature, and speed. They help optimize the blower's performance and ensure safe operation.

Accessories: Depending on the application and specific requirements, multistage centrifugal blowers may include additional accessories such as filters, dampers, silencers, and anti-vibration mounts to enhance functionality and performance.

русский

русский Español

Español عربى

عربى