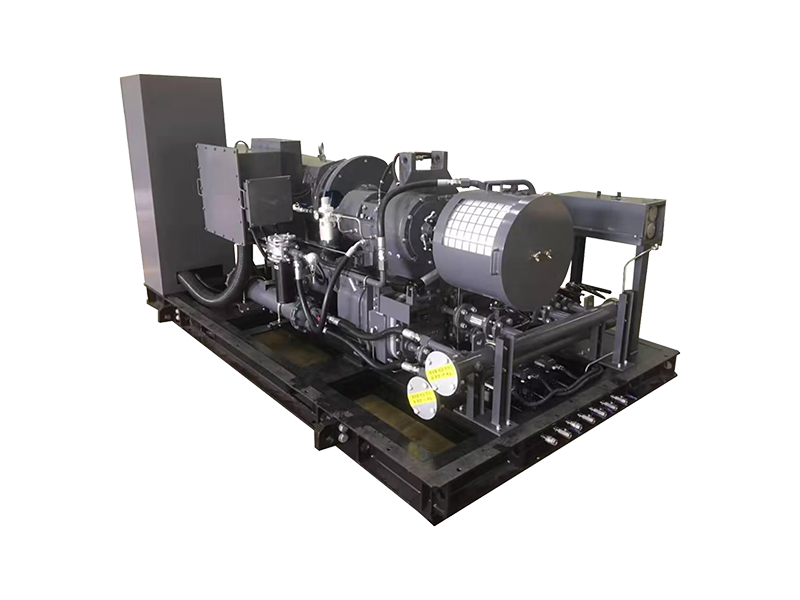

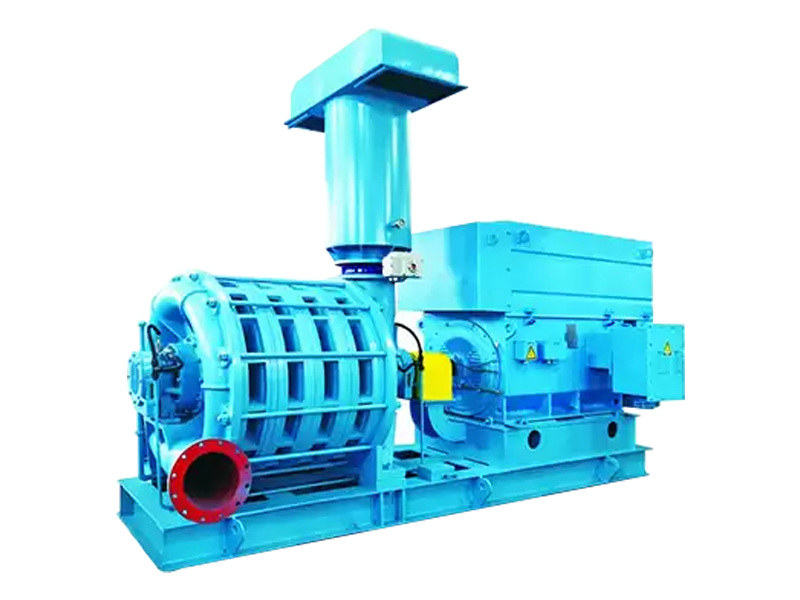

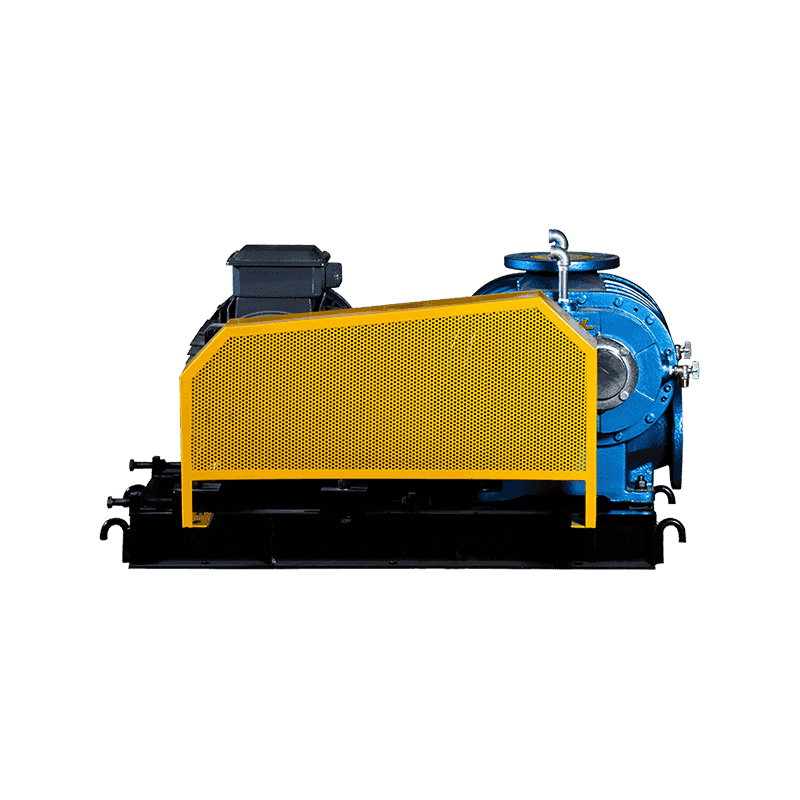

The rotary lobe blower, often called a positive displacement blower or simply a Roots blower, is a workhorse in countless industries. Its core principle is simple: two synchronized, counter-rotating lobes trap air and push it from the intake to the discharge side, creating a pulsating flow. In a clean, ideal world, these blowers would run forever. But the real world of industrial processing is messy, filled with abrasive dust, chemical vapors, and corrosive gases.

So, can a standard rotary blower handle these harsh conditions? The direct answer is: A standard, off-the-shelf blower cannot. However, a properly engineered and specifically configured rotary blower absolutely can. The distinction is critical. Success isn’t about the blower’s fundamental principle, but about the defensive armor and strategic modifications built around it.

The Invisible Enemy: Understanding Corrosive Media

Corrosion is the gradual destruction of a material by chemical or electrochemical reaction with its environment. In a blower, this typically means the internal components—the lobes, casing, and seals—are being eaten away.

Common Corrosive Media:

Chemical Vapors: Chlorine, hydrogen sulfide, sulfuric acid mist, or ammonia from wastewater treatment or chemical plants.

Acidic Gases: Exhaust from certain industrial processes.

Salt-Laden Air: Common in marine and coastal applications.

How Corrosion Attacks a Blower:

Thinning and Pitting: The cast iron or standard steel components corrode, losing material strength. This leads to a loss of efficiency and, eventually, catastrophic failure.

Lobe Seizure: As the lobes corrode, their precise clearances are lost. They can expand, warp, or develop a rough surface, leading to contact with the housing and a locked-up blower.

Seal Degradation: Standard lip seals will rapidly deteriorate when exposed to chemicals, leading to significant oil leaks or air contamination.

Fortifying the Blower: Strategies for Corrosive Applications

To combat corrosion, you don’t just buy a blower; you specify a system. Here are the key defensive measures:

1. Material Upgrade: The First Line of Defense

The most effective way to handle corrosion is to use materials that resist it.

Cast Iron with Coating: For mildly corrosive environments, a high-quality epoxy or phenolic coating on the internals can provide excellent protection at a lower cost than full alloy construction.

Stainless Steel (e.g., 304, 316): This is the go-to solution for a wide range of corrosive media. Stainless steel blowers resist oxidation and attack from many chemicals, making them ideal for food processing, pharmaceuticals, and chemical handling.

Specialized Alloys (e.g., Duplex, Super Duplex): For the most aggressive environments, such as those with high chloride content, more exotic alloys are necessary. They offer superior resistance but come at a significantly higher cost.

2. Advanced Sealing Solutions

Keeping the corrosive media out of the bearing housings is paramount.

Purging Seals: A small, continuous flow of clean, dry air (or an inert gas like nitrogen) is injected into a labyrinth seal. This creates a positive pressure barrier that prevents the corrosive process gas from reaching the sensitive bearings and oil seals.

Double Mechanical Seals: These provide a robust physical barrier, often used in conjunction with a barrier fluid for an extra layer of protection.

3. Design and Configuration

Cooling and Condensation Management: Corrosion often accelerates in the presence of moisture. Using an aftercooler to condense out vapors before they enter the blower, or specifying a higher operating temperature to keep the media in a vapor state, can be crucial.

Smooth Internal Surfaces: A polished internal surface finish leaves fewer sites for corrosion to initiate and makes it more difficult for particulate to adhere.

The Abrasive Foe: Conquering Dusty and Particulate-Laden Media

Dust is a mechanical, not chemical, attacker. It grinds away at the blower’s components like sandpaper.

Common Dusty Media:

Fly Ash: From power plants.

Wood Dust: From sawmills and woodworking.

Plastic Pellets/Powder: In pneumatic conveying.

Flour and Grain Dust: In food processing.

How Abrasion Destroys a Blower:

Clearance Erosion: The microscopic gap between the rotating lobes and the housing is critical for efficiency. Abrasive dust rapidly wears down these clearances, leading to a massive drop in volumetric efficiency and pressure capability.

Bearing Contamination: If dust infiltrates the bearing housings, it acts as a grinding paste, leading to rapid bearing failure and shaft damage.

Lobe Damage: The lobes themselves will be worn down, losing their precise profile.

Armoring the Blower: Strategies for Abrasive Applications

Fighting abrasion is about creating physical barriers and managing the contaminant.

1. Filtration: The Non-Negotiable First Step

This is the single most important factor. A high-efficiency intake filter is not an accessory; it is part of the blower system. For abrasive dust, a primary cyclone separator followed by a secondary cartridge filter is often the gold standard. The goal is to remove 99.9%+ of the particulate before it ever reaches the blower lobes.

2. Protective Coatings and Hardened Materials

Abrasion-Resistant Coatings: Applying a hard, ceramic-based coating (such as chromium carbide) to the lobes and inner casing dramatically increases their service life. The coating absorbs the wear, sacrificing itself to protect the base material.

Hardened Lobes: Using through-hardened or surface-hardened materials for the lobes provides a more durable base that wears slower than standard materials.

3. Specialized Filter Seals

Similar to purging seals, filter seals use a continuous stream of clean, filtered air to create a pressurized barrier at the shaft ends. This prevents dust from being drawn into the bearing cavities by the slight vacuum created by the rotating shaft.

4. Maintenance and Design for Service

Easily Adjustable Clearances: Some blowers are designed with adjustable clearance end-plates, allowing you to re-establish the critical lobe-to-housing gap after some wear has occurred, restoring performance without a full rebuild.

Easy-Access Inspection Ports: Ports allow for visual inspection of lobe wear without a full disassembly, enabling proactive maintenance.

The Ultimate Challenge: Combined Corrosive and Abrasive Media

Some applications present a worst-case scenario, like conveying a wet, salt-laden powder or a chemical slurry. In these cases, a multi-pronged approach is essential:

Stainless Steel Housing to resist corrosion.

Hard-Coated Lobes to resist abrasion.

Advanced Purging Seals with clean, dry air to protect the bearings from both chemical and particulate intrusion.

Robust Filtration System designed to handle the specific contaminant.

Conclusion: It’s About the System, Not Just the Blower

So, can a rotary blower handle corrosive or dusty media? The resounding answer is yes, but with a crucial caveat: it requires careful forethought and investment.

A standard blower thrown into a harsh environment will fail, and it will fail quickly and expensively. The successful application hinges on viewing the blower as the core of a larger, integrated system that includes:

Proper Material Selection

Robust Filtration and Separation

Advanced Sealing Technologies

A Proactive Maintenance Mindset

By partnering with an experienced supplier and clearly communicating the full nature of your media, you can engineer a rotary blower solution that is not just capable of surviving harsh conditions, but thriving in them for years to come. Don’t just buy a blower; specify a solution.

русский

русский Español

Español عربى

عربى