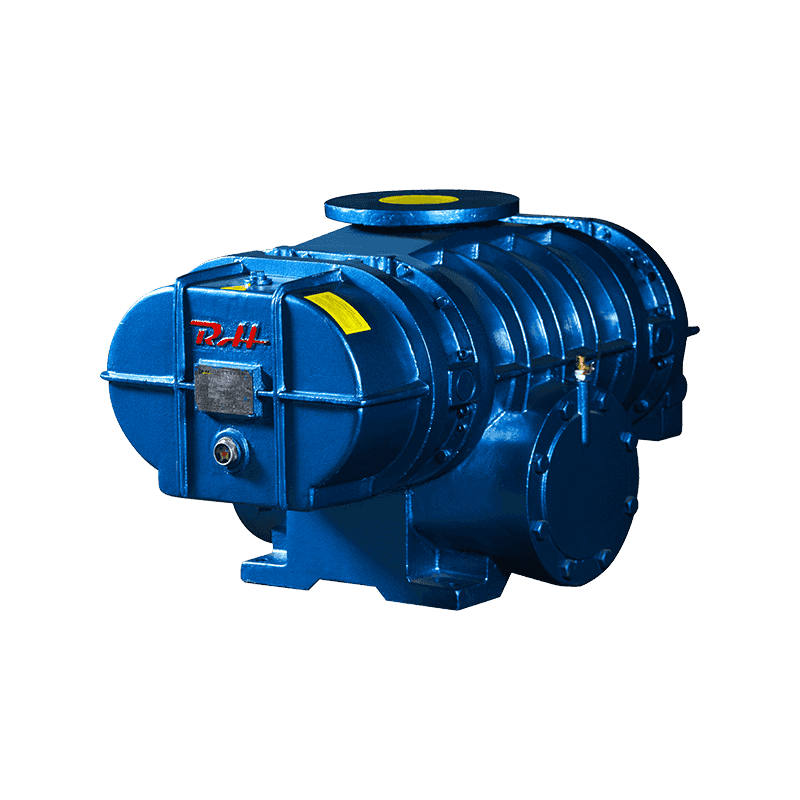

Roots rotary lobe blowers are vital pieces of equipment used to move air and gas in various industrial applications, from wastewater treatment and pneumatic conveying to combustion air supply and vacuum systems. They are known for their reliability and efficiency, but like all mechanical systems, they require proper installation and careful operation to ensure safety and long service life.

Improper handling or poor maintenance can lead not only to performance problems but also to safety risks such as overheating, mechanical failure, or even injury.

1. Understanding the Equipment Before Installation

Before any installation begins, operators and technicians should have a thorough understanding of the blower’s design, function, and requirements.

A Roots blower operates on the principle of two synchronized lobes rotating in opposite directions within a casing, pushing air or gas from the inlet to the outlet. Since it works on a positive displacement principle, it can generate significant pressure and mechanical stress if improperly handled.

Key preparatory steps include:

- Reading and following the manufacturer’s installation and operating manual.

- Reviewing the specifications for air flow rate, pressure, lubrication, and cooling.

- Understanding the blower’s direction of rotation, inlet/outlet configuration, and allowable tolerances.

- Ensuring personnel are trained in handling heavy machinery and familiar with industrial safety standards (such as ISO 9001, OSHA, or equivalent local regulations).

Having the correct technical knowledge at the start helps prevent mistakes during setup and ensures the blower operates safely from day one.

2. Proper Site Preparation

The performance and safety of a Roots rotary lobe blower depend greatly on where and how it is installed. The installation site should meet the following basic conditions:

a. Stable foundation:

Blowers should be mounted on a solid, level, vibration-resistant base. A concrete pad or steel frame designed to absorb vibration is recommended. Uneven or flexible surfaces can cause misalignment, excessive vibration, or even structural failure.

b. Adequate ventilation:

Roots blowers generate heat during operation. The room or enclosure should have sufficient airflow to prevent overheating. Overheating can damage internal seals, bearings, and lobes, and may even lead to fire hazards if ignored.

c. Accessibility:

The blower and its accessories—such as filters, silencers, and drives—should be positioned to allow easy access for inspection, cleaning, and maintenance. Crowded or enclosed setups increase risk during servicing and make troubleshooting difficult.

d. Environmental conditions:

Avoid installing the blower in areas with excessive dust, corrosive vapors, high humidity, or extreme temperatures. Environmental stress can shorten the equipment’s lifespan and compromise safety.

3. Lifting and Handling Safety

Roots rotary lobe blowers are often heavy and require mechanical assistance for transport and installation. Improper lifting techniques can lead to injury or damage.

Safety measures include:

- Always use lifting eyes or brackets provided by the manufacturer.

- Use cranes or hoists with adequate load capacity.

- Ensure slings and hooks are properly secured before lifting.

- Never lift the blower by its shaft, piping, or accessories.

- Keep all personnel clear of the lifting area while the equipment is being moved.

Additionally, when unpacking, inspect the blower for any damage that may have occurred during shipping. Damaged parts must be repaired or replaced before installation.

4. Correct Mechanical Installation

Once the site and equipment are ready, mechanical installation must be done carefully to avoid misalignment and potential mechanical failure.

a. Alignment:

The alignment between the blower shaft and the driving motor is critical. Misalignment can cause vibration, bearing damage, and coupling failure. Use precision alignment tools to verify that the shafts are perfectly parallel and level.

b. Coupling installation:

Only flexible couplings recommended by the manufacturer should be used. Rigid couplings or poor-quality components can transfer undue stress to the shafts.

c. Mounting bolts:

Tighten all bolts evenly and to the specified torque. Uneven tightening can distort the housing or cause air leakage.

d. Piping connection:

Avoid using the blower casing to support the weight of the connected piping. Use separate pipe supports to prevent mechanical strain on the blower. Flexible joints or expansion bellows should be installed to absorb vibration and thermal expansion.

5. Electrical and Control Safety

Roots blowers are usually driven by electric motors, requiring attention to electrical safety standards.

a. Qualified personnel:

Only certified electricians should handle electrical connections. Improper wiring can cause motor damage or electrical shock.

b. Grounding:

Ensure the motor and control panel are properly grounded. Grounding protects against short circuits and electrical faults.

c. Motor protection:

Install overload protection devices, fuses, and circuit breakers according to specifications. These devices safeguard both the motor and blower from overcurrent or voltage spikes.

d. Emergency stop controls:

Always provide an easily accessible emergency stop switch in the control panel or near the blower for immediate shutdown during emergencies.

e. Wiring checks:

After connection, inspect the wiring for loose connections or exposed wires. Conduct insulation resistance tests before powering the blower.

6. Lubrication and Cooling Safety

Lubrication is critical to the performance and longevity of a Roots blower. The bearings, gears, and seals depend on proper lubrication to prevent friction and overheating.

Safety tips for lubrication:

- Use only the recommended oil or grease grade specified by the manufacturer.

- Never mix different types or brands of lubricants.

- Check oil levels before startup and periodically during operation.

- Replace oil at regular intervals based on operating hours and environmental conditions.

- Keep lubrication points clean and free from dust and debris.

For blowers equipped with cooling systems (air- or water-cooled types), ensure that cooling ducts or water lines are properly connected and free of blockages. Overheating can cause catastrophic damage to internal components.

7. Pre-Startup Safety Checks

Before starting a Roots blower for the first time—or after maintenance—it’s essential to perform a full pre-start inspection. This helps prevent accidents caused by improper setup.

Checklist before startup:

- Verify that all bolts, couplings, and supports are properly tightened.

- Check for foreign objects inside the inlet and outlet ports.

- Ensure that the lubrication system is filled and functioning.

- Confirm that safety guards and covers are in place.

- Verify correct motor rotation direction (briefly jog the motor if necessary).

- Ensure all valves are properly positioned and not fully closed during startup.

- Confirm that pressure relief valves and filters are correctly installed.

These checks reduce the risk of damage and ensure a smooth, controlled startup process.

8. Safe Operation Practices

During operation, the main focus should be on maintaining stable conditions, monitoring performance, and avoiding overload.

Key operational precautions:

- Never operate the blower beyond its rated pressure or temperature limits.

- Keep suction filters clean to prevent overloading.

- Avoid sudden changes in load or pressure that could cause mechanical shock.

- Monitor vibration, noise, and temperature regularly—unusual readings often indicate developing problems.

- Ensure that all safety guards remain in place during operation.

- Do not open inspection covers or disconnect piping while the blower is running.

- Maintain clear communication between operators and control room personnel.

Temperature monitoring is especially important. If the discharge temperature exceeds the allowable limit, the blower should be stopped immediately to avoid internal damage.

9. Maintenance and Inspection Safety

Regular maintenance extends the life of a Roots blower and prevents unsafe operating conditions. However, maintenance itself must be performed safely.

a. Lockout/Tagout (LOTO):

Before performing any maintenance, disconnect power and apply lockout/tagout procedures to prevent accidental startup.

b. Pressure release:

Ensure that all internal pressure has been released before opening any covers or removing connections.

c. Cooling period:

Allow the blower to cool down after operation before handling or dismantling any parts.

d. Personal protective equipment (PPE):

Wear appropriate PPE, including gloves, safety glasses, and hearing protection, especially in noisy environments.

e. Inspection intervals:

Regularly inspect for signs of wear such as oil leakage, loose fasteners, and abnormal vibration. Replace worn components promptly.

f. Cleaning:

Keep the blower exterior and surrounding area clean to prevent dust accumulation, which can affect cooling and lubrication systems.

10. Common Hazards and How to Avoid Them

Even with proper precautions, certain risks are inherent to blower systems. Recognizing them early helps prevent accidents.

| Hazard | Cause | Prevention |

| Overheating | Clogged filters, overpressure, poor ventilation | Maintain clean filters, ensure proper airflow, use temperature monitoring |

| Excessive vibration | Misalignment, bearing wear, unbalanced drive | Regular alignment checks, replace worn bearings |

| Oil leakage | Damaged seals or overfilled oil chamber | Inspect seals, maintain correct oil level |

| Noise exposure | Mechanical vibration, high discharge velocity | Use silencers and acoustic enclosures |

| Electrical shock | Faulty wiring, poor grounding | Use certified electricians, inspect regularly |

| Explosion risk | Handling flammable gases without precautions | Use gas-specific blowers with explosion-proof designs |

11. Emergency Shutdown Procedures

In the event of an abnormal situation—such as excessive temperature, unusual vibration, or unexpected pressure increase—operators should follow a standard shutdown procedure:

- Immediately press the emergency stop button.

- Cut off electrical power to the motor.

- Close the inlet and discharge valves gradually.

- Allow the blower to cool before inspection.

- Identify and correct the cause before restarting.

Documenting emergency procedures and ensuring all staff are trained to follow them is a vital part of workplace safety.

12. Training and Documentation

Safety is not just about procedures—it’s also about people. Operators, technicians, and supervisors must receive proper training on blower operation, troubleshooting, and emergency response.

Additionally, all maintenance activities and inspections should be documented. A well-kept maintenance log helps identify patterns, schedule replacements, and verify compliance with safety standards.

Conclusion

Roots rotary lobe blowers are dependable machines when installed and operated correctly. However, their reliability depends heavily on observing strict safety measures at every stage—from lifting and alignment to operation and maintenance.

Following manufacturer instructions, ensuring proper ventilation and lubrication, conducting pre-start checks, and maintaining clear emergency procedures all contribute to a safer, more efficient work environment.

By combining good engineering practice with diligent monitoring and safety discipline, operators can maximize the performance and lifespan of their Roots blowers—while keeping personnel and facilities secure.

русский

русский Español

Español عربى

عربى