In many industrial environments, the start-up phase of mechanical equipment is one of the most critical moments in its operating cycle. Motors, pumps, compressors, fans, and other machinery often experience their highest mechanical and electrical stresses during start-up. These stresses, if not managed properly, can lead to premature wear, increased maintenance costs, unexpected shutdowns, or even catastrophic equipment failure.

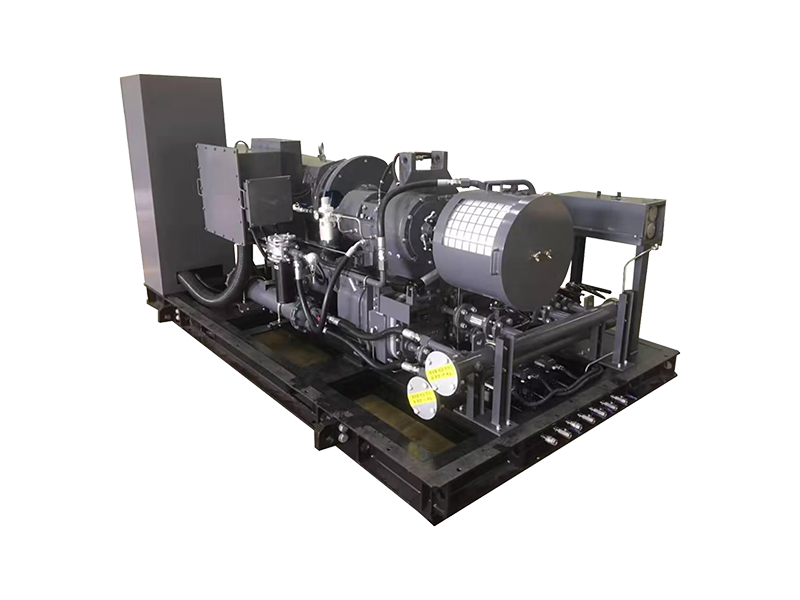

The Frequency Conversion Starting Cabinet—also known as a variable frequency drive (VFD) starting cabinet—has emerged as an important solution for reducing these risks. By controlling voltage and frequency during start-up, it allows machinery to begin operation in a more controlled manner.

1. Understanding the Start-Up Problem in Mechanical Equipment

Most industrial motors are designed to run at a fixed speed under steady-state conditions. However, the moment of start-up is quite different:

1.1 Sudden Inrush Current

Conventional direct-on-line (DOL) starting can draw 6–8 times the motor’s rated current. This heavy inrush can result in:

- Excess heating inside the motor windings

- Electrical stress on insulation

- Disturbances in the facility’s power network

- Nuisance tripping of protection devices

1.2 Sharp Mechanical Shock Loads

The sudden application of full torque can transmit shock to:

- Gearboxes

- Couplings

- Pumps

- Fans

- Conveyors

- Bearings and shafts

Such shocks can accelerate component wear or misalignment.

1.3 Instability During Acceleration

Different mechanical systems—especially those involving high inertia loads—require a gradual acceleration curve to prevent overshooting, vibration, cavitation, or surging.

Given these concerns, industries began searching for a start-up solution capable of reducing both electrical and mechanical stress. This is where Frequency Conversion Starting Cabinets became relevant.

2. What a Frequency Conversion Starting Cabinet Does

A Frequency Conversion Starting Cabinet controls the motor’s operating frequency as it powers up. Because motor speed is directly proportional to frequency, this approach ensures a smoother, gentler acceleration process. Instead of jumping immediately to full speed, the equipment follows a controlled ramp-up profile.

Key functions include:

- Adjusting the output frequency

- Regulating voltage proportionally

- Monitoring load conditions

- Managing torque delivery

This controlled method of start-up produces several benefits that directly protect mechanical equipment.

3. How Frequency Conversion Starting Cabinets Protect Equipment

3.1 Reducing Electrical Stress During Start-Up

The cabinet prevents the sudden surge of current that typically accompanies DOL starting:

- Inrush current drops from 600–800% of rated current to around 100–120%

- The motor runs cooler and experiences less thermal strain

- Power distribution networks remain stable

By lowering the electrical impact on motor windings and the facility’s circuitry, the system indirectly extends the lifespan of connected machinery and prevents issues related to overheating or insulation breakdown.

3.2 Delivering Smooth, Controlled Acceleration

One of the biggest mechanical advantages of frequency conversion starting is the ability to ramp up speed gradually. A controlled acceleration:

- Eliminates shock loads on gearboxes, couplings, and shafts

- Prevents sudden torque spikes

- Reduces vibration during start-up

- Lowers stress on foundations and support structures

This smoother process protects precision components and minimizes the risk of mechanical imbalance, misalignment, or damage to delicate equipment such as pumps or conveyors.

3.3 Extending the Life of Bearings and Rotating Components

Bearings are among the most vulnerable components during start-up. High torque shock loads can cause:

- Micro-pitting

- Excessive friction

- Premature wear

- Unexpected bearing failures

The controlled torque delivered by a Frequency Conversion Starting Cabinet results in:

- Less mechanical friction

- Lower radial and axial loads

- A more consistent lubrication film during initial motion

Over time, this translates into fewer maintenance interventions and longer operating cycles for rotating machinery.

3.4 Protecting Pumps From Hydraulic Stress

Pumps are particularly sensitive during start-up. Sudden full-speed operation can cause:

- Water hammer

- Cavitation

- Pressure spikes

- Rapid changes in flow rate

A frequency-controlled start helps the pump accelerate gradually so that pressure builds smoothly and fluid flow stabilizes. This not only reduces mechanical stress but also protects piping systems and valves connected downstream.

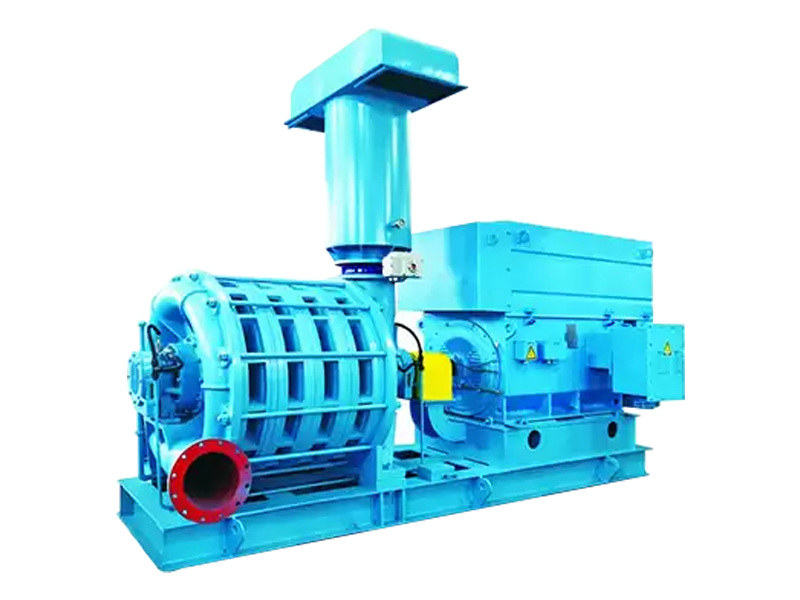

3.5 Minimizing Belt Slippage and Impact on Transmission Components

In systems involving belt-driven components—such as fans, blowers, or conveyor systems—sudden acceleration can cause belts to slip or jerk, leading to:

- Premature belt wear

- Pulley damage

- Misalignment

Frequency conversion start-up allows belts to engage progressively and uniformly. This stabilizes transmission components and reduces the need for frequent realignment or replacement.

3.6 Protecting Fans and High-Inertia Loads

High-inertia equipment, such as large fans or flywheel systems, often struggles with DOL starting due to the instant demand for high torque. A Frequency Conversion Starting Cabinet:

- Supplies the necessary torque in a controlled manner

- Ensures stable acceleration without thermal overload

- Prevents the motor from stalling or overheating

This is particularly important in ventilation systems, cement plants, steel mills, and heavy industrial settings.

3.7 Reducing Noise and Vibration During Start-Up

Mechanical noise is a clear indicator of stress, imbalance, or shock loads. By delivering torque in a smooth, controlled fashion:

- Operating noise during start-up is significantly reduced

- Vibration amplitudes are lower

- Mechanical connections remain more stable

The result is improved reliability and safer working conditions.

4. Additional Protective Functions Built Into Many Frequency Conversion Starting Cabinets

Depending on the manufacturer and model, additional protection and monitoring features may also be included:

- Overload protection

- Under-voltage and over-voltage alarms

- Phase loss and imbalance protection

- Overheating protection for the motor

- Short-circuit or ground fault detection

- Soft stop features to prevent abrupt shutdowns

- Automatic fault logging for easier maintenance

These advanced functions create a more resilient and intelligent equipment protection system, giving maintenance teams better insight into operating conditions.

5. Long-Term Benefits of Using a Frequency Conversion Starting Cabinet

Beyond immediate protection, there are several long-term advantages for facility operators:

5.1 Reduced Maintenance and Downtime

Fewer mechanical shocks and smoother operation result in:

- Lower maintenance frequency

- Less unscheduled downtime

- Lower long-term repair costs

5.2 Improved Energy Efficiency

While the main purpose is equipment protection, the ability to regulate speed also allows motors to run at optimal efficiency under varying loads.

5.3 Increased System Stability

Stable electrical and mechanical behavior during start-up helps maintain consistent industrial processes, which is particularly important in production lines where disruptions can cause product quality issues.

6. Best Practices to Maximize Protection

To get the most out of a Frequency Conversion Starting Cabinet, operators should consider the following:

- Ensure proper sizing of both the cabinet and the motor

- Set the acceleration and deceleration curves according to the mechanical load

- Conduct regular inspections of cabinet components, including cooling fans and power modules

- Monitor parameter logs to detect changes in equipment behavior

- Follow manufacturer guidelines for installation, grounding, and cable routing

A well-configured system provides far greater protection than a cabinet that is improperly set up.

Conclusion

A Frequency Conversion Starting Cabinet plays a crucial role in safeguarding mechanical equipment during start-up by controlling the acceleration process, reducing electrical and mechanical stress, and ensuring a smoother transition into operating speed. Whether the machinery is part of a pumping station, HVAC system, industrial conveyor, or manufacturing line, controlled start-up significantly improves equipment reliability and longevity.

While the technology is not a universal solution for every application, its ability to minimize shock loads, enhance safety, protect motors and mechanical systems, and reduce operational costs makes it an important tool across many industries. Through thoughtful configuration and proper maintenance, users can maximize these benefits and ensure that their equipment starts reliably, consistently, and safely every time.

русский

русский Español

Español عربى

عربى