In the world of industrial air movement and gas handling, blowers play a crucial role in providing the necessary air pressure and flow for a wide variety of applications. Among the many types of blowers used in industries such as wastewater treatment, pneumatic conveying, chemical processing, and power generation, two designs stand out: multistage centrifugal blowers and positive displacement blowers.

Although both are designed to move air or gas from one place to another, they function on very different principles. Understanding these differences is essential for engineers, plant operators, and purchasing managers who need to select the right equipment for their systems.

1. Basic Operating Principles

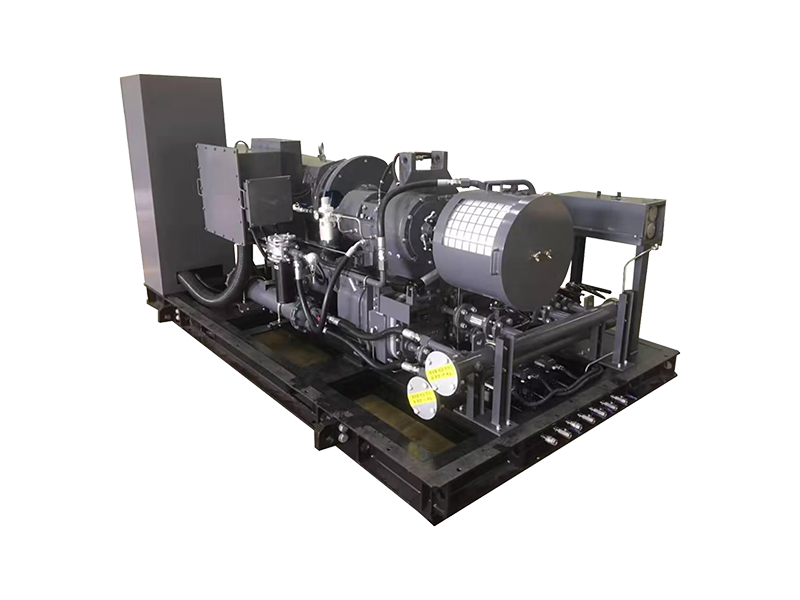

Multistage Centrifugal Blowers

Multistage centrifugal blowers operate based on the principle of dynamic compression. Air enters the center (eye) of a rapidly rotating impeller and is flung outward by centrifugal force. As the air moves through the impeller blades, its velocity increases. The high-speed air then passes through stationary diffusers, where kinetic energy is converted into pressure energy.

In a multistage configuration, several impellers are arranged in series. Each stage incrementally increases the pressure of the air, resulting in a higher overall discharge pressure than what a single impeller could achieve. This step-by-step compression process makes multistage centrifugal blowers suitable for applications that demand moderate to high pressures with a continuous, pulsation-free flow.

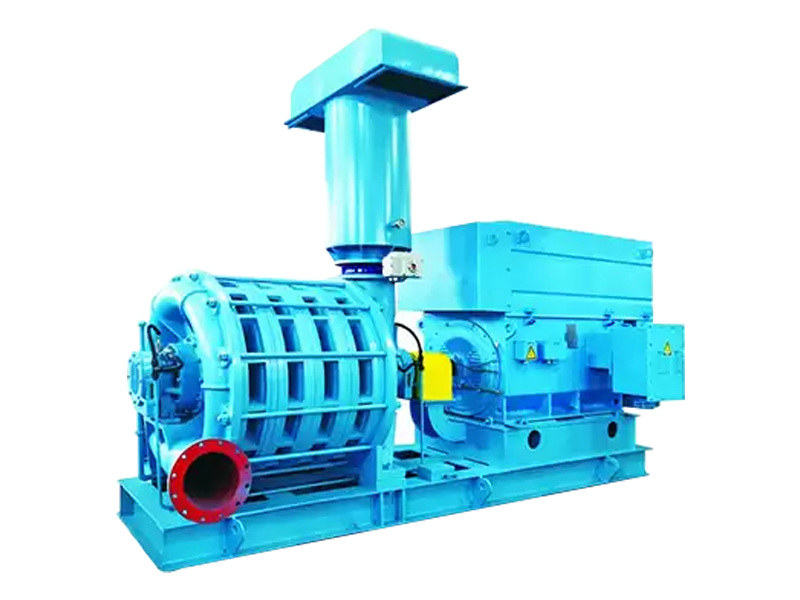

Positive Displacement Blowers

Positive displacement blowers, in contrast, work by trapping a fixed volume of air and physically pushing it from the inlet to the outlet. They do not rely on high rotational speeds or velocity energy to compress the air. Instead, they operate through mechanical displacement—commonly achieved using rotary lobes, screws, or vanes.

Each revolution of a positive displacement blower delivers a nearly constant volume of air, regardless of the pressure in the system. The pressure increase occurs downstream as the trapped air is forced into the system resistance. This operating principle allows positive displacement blowers to deliver consistent air volumes even when system pressure fluctuates.

2. Key Design Differences

The fundamental difference in how these blowers move and compress air leads to distinct design characteristics.

-

Impeller vs. Rotor Mechanism:

Multistage centrifugal blowers use impellers and diffusers to build pressure through velocity conversion, while positive displacement blowers use intermeshing rotors or lobes to trap and move fixed air pockets. -

Number of Stages:

A centrifugal blower often has multiple impellers (stages) to achieve higher pressures. Positive displacement blowers, however, typically have only one compression chamber, and pressure is built up externally by the resistance in the connected system. -

Speed of Operation:

Multistage centrifugal blowers operate at high rotational speeds—often thousands of revolutions per minute—to achieve the required velocity and pressure. Positive displacement blowers operate at relatively lower speeds, relying on volume displacement rather than velocity. -

Flow Path:

In a centrifugal blower, air moves radially outward through curved blades and diffusers, while in a positive displacement blower, air moves linearly through the housing as the rotors rotate.

These differences in design directly affect performance, efficiency, and the nature of air delivery, which we will explore next.

3. Pressure and Flow Characteristics

Multistage Centrifugal Blowers

Centrifugal blowers are dynamic machines, meaning their performance depends on system resistance. When the backpressure in the system increases, the flow rate from a centrifugal blower decreases. As a result, they are best suited for applications that require variable flow but relatively stable operating conditions.

They can efficiently provide moderate to high pressures, often ranging from 3 psi to 20 psi (or even higher in specialized configurations), depending on the number of stages and design parameters.

Positive Displacement Blowers

Positive displacement blowers are constant volume machines. They deliver a nearly fixed amount of air per revolution regardless of the system’s backpressure. However, as the system resistance increases, the blower’s power demand also rises because it must work harder to overcome the increased pressure.

These blowers typically operate at lower pressure ranges, often between 1 psi and 15 psi, though certain screw-type models can reach higher pressures. Their consistent volume output makes them ideal for processes where stable airflow is critical.

4. Efficiency and Energy Consumption

Energy efficiency is one of the most important considerations in selecting industrial blowers, as they often run continuously and represent a significant portion of operational costs.

Multistage Centrifugal Blowers

Centrifugal blowers are generally more efficient when operated close to their design point—the combination of pressure and flow for which they were engineered. When running at or near this optimal point, the energy conversion from kinetic to pressure energy is highly effective.

Modern designs also include variable frequency drives (VFDs) that allow operators to adjust blower speed according to demand, further improving energy efficiency. However, if system conditions deviate significantly from the design point, efficiency can drop.

Positive Displacement Blowers

Positive displacement blowers tend to be less efficient than centrifugal types at high flow rates because they rely on mechanical movement and have more internal friction. However, they maintain steady efficiency across a wide range of pressures and flows, particularly in applications with varying system backpressures.

For processes requiring a constant volume of air regardless of pressure changes, positive displacement blowers can offer predictable and stable energy use.

5. Airflow Quality and Pulsation

A major difference between the two blower types is the nature of airflow they deliver.

-

Multistage Centrifugal Blowers produce smooth, continuous airflow with minimal pulsation. This steady stream of air is ideal for processes sensitive to fluctuations, such as aeration in wastewater treatment or combustion air supply in boilers.

-

Positive Displacement Blowers, on the other hand, generate pulsating airflow due to the cyclic nature of rotor movement. Pulsations can be mitigated by using silencers or pulsation dampeners, but they cannot be completely eliminated.

This difference in flow smoothness often determines the suitability of each blower type for specific applications.

6. Noise and Vibration

Because multistage centrifugal blowers operate at high speeds but produce continuous airflow, they typically generate lower noise levels than positive displacement blowers of equivalent capacity. The absence of pulsation also means less vibration and smoother operation.

Positive displacement blowers, especially lobe types, can be noisy and vibratory due to the periodic trapping and release of air. While modern designs include acoustic enclosures and precision balancing to reduce noise, centrifugal blowers generally remain quieter and more stable in operation.

7. Maintenance and Reliability

Maintenance requirements differ significantly between these two blower types due to their internal mechanisms and operating principles.

Multistage Centrifugal Blowers

These blowers have few moving parts in direct contact, which reduces mechanical wear. Routine maintenance mainly involves checking bearings, seals, and lubrication systems. However, the high-speed nature of operation demands precision balancing and periodic inspection to ensure long-term reliability.

Positive Displacement Blowers

Positive displacement blowers experience more mechanical wear because of the close tolerances between rotors and casing. Regular maintenance includes checking clearances, replacing timing gears, inspecting seals, and maintaining lubrication. While these blowers are robust, they may require more frequent servicing than centrifugal models.

Overall, multistage centrifugal blowers tend to have lower long-term maintenance costs, while positive displacement blowers offer easier on-site repair and rebuild options.

8. Control and Modulation

Multistage centrifugal blowers respond well to speed control through variable frequency drives, allowing fine-tuned regulation of flow and pressure. This flexibility makes them ideal for processes where demand fluctuates over time.

Positive displacement blowers are less responsive to speed control, as their output volume is fixed per revolution. Flow control often requires bypass valves or inlet throttling, which can lead to energy inefficiency if not carefully managed.

9. Typical Applications

The choice between multistage centrifugal and positive displacement blowers largely depends on the specific needs of the application.

Common Uses of Multistage Centrifugal Blowers:

- Wastewater treatment aeration

- Combustion air supply in furnaces and boilers

- Cooling and drying systems

- Chemical and petrochemical processes

- Pneumatic conveying of powders

- Industrial vacuum systems

Common Uses of Positive Displacement Blowers:

- Pneumatic conveying systems with fluctuating resistance

- Vacuum generation

- Gas boosting and compression

- Wastewater aeration in smaller systems

- Grain handling and material transport

Both types can serve similar markets, but their performance advantages make them better suited to specific tasks within those markets.

10. Cost Considerations

Initial purchase costs for multistage centrifugal blowers are generally higher than those for positive displacement blowers, mainly due to the complexity of design and precision manufacturing. However, centrifugal blowers often offer lower operating and maintenance costs over time, especially in continuous-duty applications with stable conditions.

Positive displacement blowers may be more economical for smaller systems, intermittent use, or installations with varying load demands. Evaluating total lifecycle costs—including energy, maintenance, and downtime—is essential when making a purchasing decision.

11. Summary of Key Differences

| Feature | Multistage Centrifugal Blowers | Positive Displacement Blowers |

|---|---|---|

| Operating Principle | Dynamic compression via high-speed impellers | Mechanical displacement via rotors/lobes |

| Flow Type | Continuous, smooth airflow | Pulsating, constant volume |

| Pressure Range | Moderate to high | Low to moderate |

| Efficiency | High at design point | Consistent across pressure variations |

| Noise and Vibration | Low | Higher, requires dampening |

| Maintenance | Low | Higher, more mechanical wear |

| Control | Easy with VFD | Limited; may require valves |

| Best Applications | Stable, continuous airflow systems | Variable resistance or vacuum systems |

12. Choosing the Right Blower

Selecting between a multistage centrifugal blower and a positive displacement blower depends on several factors:

- Required pressure and flow rate

- Variability of system resistance

- Desired airflow smoothness

- Energy efficiency goals

- Maintenance capabilities and downtime tolerance

- Noise and vibration constraints

For operations needing high efficiency, quiet operation, and smooth continuous airflow, multistage centrifugal blowers are generally preferred. For systems requiring constant air delivery under fluctuating pressure conditions, positive displacement blowers offer reliability and predictable performance.

Conclusion

While both multistage centrifugal blowers and positive displacement blowers serve the same basic purpose—to move air or gas through a system—they achieve it in fundamentally different ways. Multistage centrifugal blowers rely on dynamic compression and high-speed impellers to generate smooth, efficient airflow at moderate to high pressures. Positive displacement blowers use mechanical displacement to deliver a fixed volume of air regardless of pressure variations.

Understanding these differences helps operators and engineers select the most suitable blower for their specific process requirements. Making the right choice not only improves system performance but also optimizes energy consumption, reduces maintenance costs, and extends equipment life.

Ultimately, both technologies have their place in modern industry—it’s the understanding of their distinct capabilities that ensures each is used to its greatest advantage.

русский

русский Español

Español عربى

عربى