If you’re involved in industrial manufacturing, wastewater treatment, or any process that requires moving air or gas, you’ve likely encountered the term “rotary lobe blower.” Often referred to as positive displacement blowers or simply PD blowers, these workhorses are critical components in countless applications. But what exactly are they, how do they work, and how do you know if one is right for your operation? This guide breaks down everything you need to know.

What is a Rotary Lobe Blower and How Does It Work?

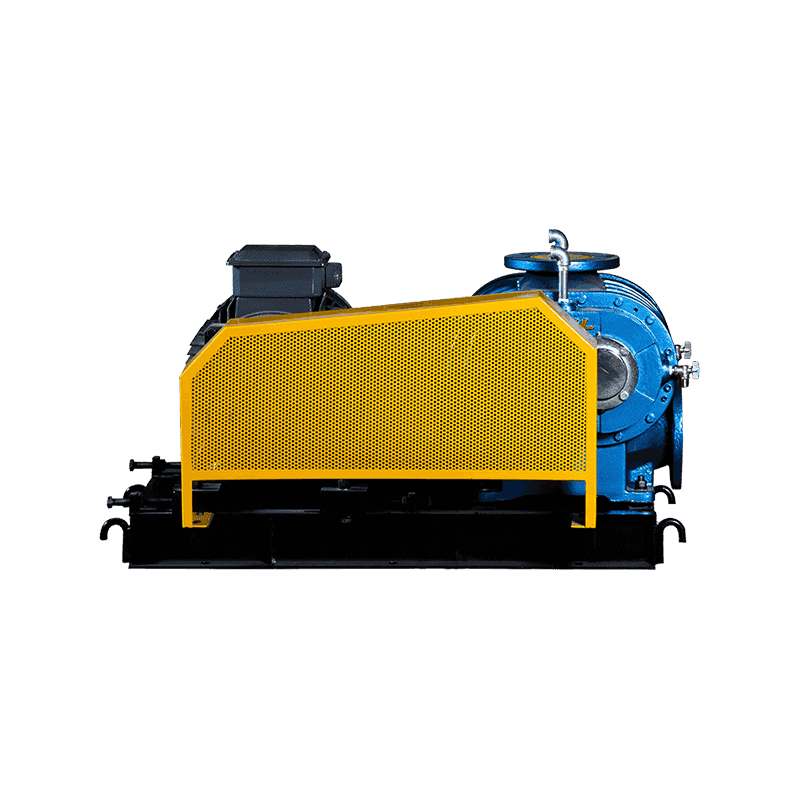

At its core, a rotary lobe blower is a simple yet highly effective machine designed to move a constant volume of air or gas against a moderate pressure. Its operation is based on the positive displacement principle.

Inside the blower’s housing, two identical, symmetrically-shaped, lobed rotors spin in opposite directions. These rotors are precisely machined to extremely tight tolerances. As they rotate, air is trapped in the pockets between the lobes and the blower casing. The rotation carries this air from the intake side to the discharge side, where it is forced out into the system.

Three key characteristics define this process:

- Non-Contacting: The rotors never touch each other, and they do not touch the housing. This is achieved through very precise engineering and timing gears that synchronize their movement.

- Pulsation: The air is delivered in discrete pulses rather than a perfectly smooth flow. Modern three-lobe designs have minimized this pulsation compared to older two-lobe models, making operation quieter and more efficient.

- Oil-Free Operation: In its most common configuration, the compression chamber has no lubrication. This means the air being moved remains entirely uncontaminated by oil, which is a critical requirement for many applications.

Common Industrial Applications for Rotary Blowers

The unique ability to deliver oil-free air reliably makes these blowers indispensable across a wide range of industries. Understanding their industrial applications is key to seeing their value.

- Wastewater Treatment: This is one of the largest applications. Rotary blowers provide the air required for the aeration process in treatment tanks. By pumping oxygen into the wastewater, they promote the growth of aerobic bacteria that break down organic matter and pollutants.

- Pneumatic Conveying: In food processing, plastics, cement, and pharmaceutical plants, blowers are used to move dry bulk materials like powder, granules, and pellets through pipelines. They can be used for either pressure or vacuum systems to transport materials efficiently and cleanly.

- Industrial Vacuum Systems: Large-scale central vacuum systems in factories often use rotary lobe blowers as their vacuum source. They are capable of handling large volumes of air and some entrained solids, making them ideal for cleaning operations in woodworking, metalworking, and food processing plants.

- Aquaculture: Similar to wastewater treatment, fish and shrimp farms use blowers to aerate ponds and tanks, ensuring a healthy, oxygen-rich environment for high-density aquaculture.

- Combustion Air Supply: They can be used to provide a controlled, consistent supply of air to burners and furnaces, improving combustion efficiency.

Key Advantages and Benefits

Why choose a rotary lobe blower over other types of air-moving equipment like centrifugal blowers or compressors? The benefits are clear:

- Oil-Free Air Delivery: This is the paramount advantage for sensitive applications. It eliminates the risk of product contamination in food and pharma and prevents fouling in processes like aeration.

- High Volumetric Efficiency: Because they are positive displacement machines, they deliver a nearly constant cubic feet per minute (CFM) of flow, regardless of discharge pressure changes (within their design limits). This makes them highly predictable and reliable.

- Relatively Low Maintenance: With no internal lubrication in the air stream, there are fewer consumables and less risk of failure due to oil-related issues. Maintenance typically involves routine checks of bearings, seals, and timing gears.

- Durability and Long Service Life: Built with robust materials and a simple operating principle, a well-maintained rotary blower can operate reliably for decades.

- Ability to Handle Wet Gases: They are more tolerant of moisture in the air stream compared to some other compressor types, which is a significant benefit in applications like aeration.

Important Considerations for Selection and Maintenance

Selecting the right rotary blower for sale isn’t just about picking a model; it’s about matching the machine to your specific needs.

Selection Criteria:

- Flow Rate (CFM): Determine the volume of air your process requires.

- Pressure (PSI): Understand the system resistance the blower must overcome. Remember, for positive displacement blowers, power consumption is directly tied to pressure.

- Motor Sizing: Ensure the drive motor is correctly sized for the maximum pressure and flow required to avoid overloading.

- Options and Controls: Consider inlet filters, silencers, and variable frequency drives (VFDs). A VFD for blower can offer massive energy savings by allowing the motor speed to be adjusted to match demand, rather than running flat-out and bleeding off excess air.

Essential Maintenance Tips:

Proper blower maintenance is non-negotiable for longevity.

- Air Filtration: The single most important maintenance task is regularly changing the intake air filter. Ingress of dirt and dust is the primary cause of internal wear and performance loss.

- Check Belts and Couplings: For belt-driven models, check for proper tension and wear.

- Monitor Temperature and Vibration: Regularly check bearing temperatures and listen for unusual vibrations or noises, which can be early indicators of an issue.

- Scheduled Service: Adhere to the manufacturer’s recommended service intervals for gear oil changes and bearing inspections.

Conclusion

The rotary lobe blower is a testament to the power of elegant engineering. Its simple, robust, and efficient design has made it a cornerstone of modern industry. Whether it’s cleaning our water, moving our food, or supplying vital oxygen, its role is often unseen but absolutely critical. By understanding its principles, benefits, and proper care, you can ensure that your blower system remains a reliable and efficient asset for years to come. When considering a new system, always focus on your specific requirements for flow, pressure, and air purity to make the perfect choice for your operation.

русский

русский Español

Español عربى

عربى