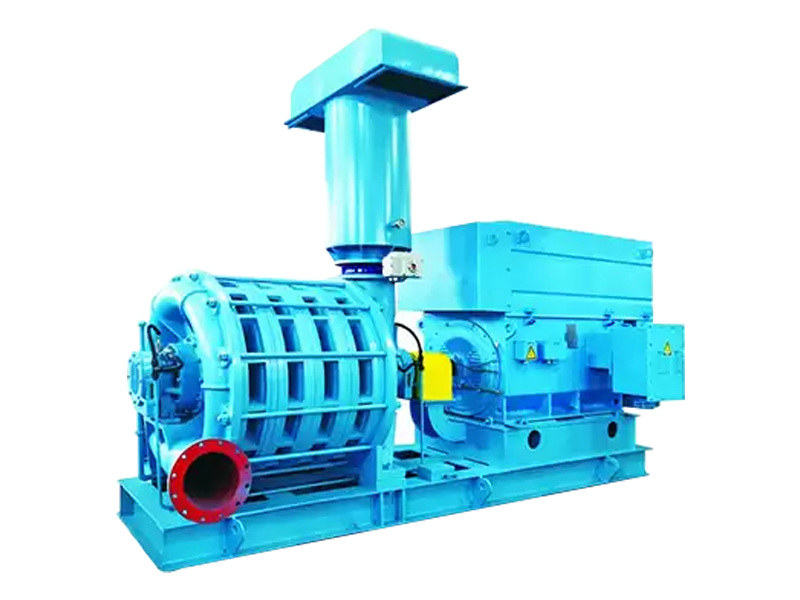

In the realm of industrial air management, multistage centrifugal blowers stand as the epitome of efficiency, reliability, and power. Engineered to meet the demanding needs of sectors ranging from manufacturing and chemical processing to HVAC systems, these blowers are indispensable when consistent, high-pressure airflow is paramount.

Fundamental Design and Operation

At its core, a multistage centrifugal blower operates by sequentially accelerating air through multiple impeller stages arranged on a common shaft. Each stage comprises a rotating impeller and a stationary diffuser or volute casing, which converts kinetic energy into pressure. Unlike single-stage blowers, the multistage configuration allows for incremental pressure buildup, culminating in significantly higher discharge pressures without compromising volumetric flow rates.

This staged approach enables the blower to maintain optimal efficiency even under high-pressure conditions, making it superior to conventional single-stage centrifugal blowers when applications demand elevated pressures or extended operating ranges.

Key Features and Advantages

High Pressure Generation

The hallmark of multistage centrifugal blowers is their ability to generate substantial pressure differentials. By channeling air through successive impellers, these blowers achieve pressure increases that can exceed several atmospheres, rendering them ideal for processes requiring forced ventilation, pneumatic conveying, or combustion air supply.

Energy Efficiency and Durability

Designed with aerodynamic precision, impeller blades in multistage blowers minimize turbulence and energy loss. This translates to superior energy efficiency, lowering operational costs over the blower’s lifecycle. Furthermore, robust construction materials and balanced rotating components ensure durability, enabling continuous operation in demanding industrial environments.

Versatility and Customization

Multistage centrifugal blowers can be tailored to specific requirements. Parameters such as the number of stages, impeller diameter, blade geometry, and casing design are customizable to meet precise airflow and pressure specifications. This flexibility allows seamless integration across diverse industrial processes, including drying, aeration, combustion, and chemical vapor handling.

Reduced Noise and Vibration

Advanced engineering and precision balancing reduce mechanical vibrations and operational noise. When coupled with sound-attenuating casings or enclosures, multistage blowers provide a quieter work environment, which is crucial in sensitive industrial or commercial applications.

Applications Across Industries

Multistage centrifugal blowers serve as the backbone in many critical operations:

Power Generation: Supplying high-pressure combustion air to boilers and furnaces.

Chemical and Petrochemical: Facilitating pneumatic transport of powders and gases, ensuring controlled pressure environments.

Wastewater Treatment: Providing aeration for biological processes, enhancing oxygen transfer efficiency.

HVAC Systems: Delivering pressurized air in large-scale ventilation, heating, and cooling installations.

Their capability to maintain consistent pressure and airflow regardless of fluctuating process conditions makes them indispensable in these scenarios.

Operational Considerations

Optimal performance of multistage centrifugal blowers hinges on meticulous selection and maintenance. Factors such as operating speed, temperature, gas composition, and pressure requirements must be precisely matched with blower specifications to maximize efficiency and prevent premature wear.

Regular inspection of impeller wear, bearing lubrication, and vibration levels is essential to sustain longevity and avert costly downtime. Additionally, incorporating variable frequency drives (VFDs) can provide dynamic control over blower speed, enhancing energy savings and process adaptability.

In an industrial landscape that demands unwavering reliability and efficiency, multistage centrifugal blowers excel as the quintessential solution for high-pressure airflow applications. Their engineered sophistication, adaptability, and operational excellence deliver measurable benefits in performance and cost-effectiveness. For industries seeking to elevate their air handling capabilities without compromise, these blowers represent a strategic investment — one that harmonizes power, precision, and longevity.

русский

русский Español

Español عربى

عربى