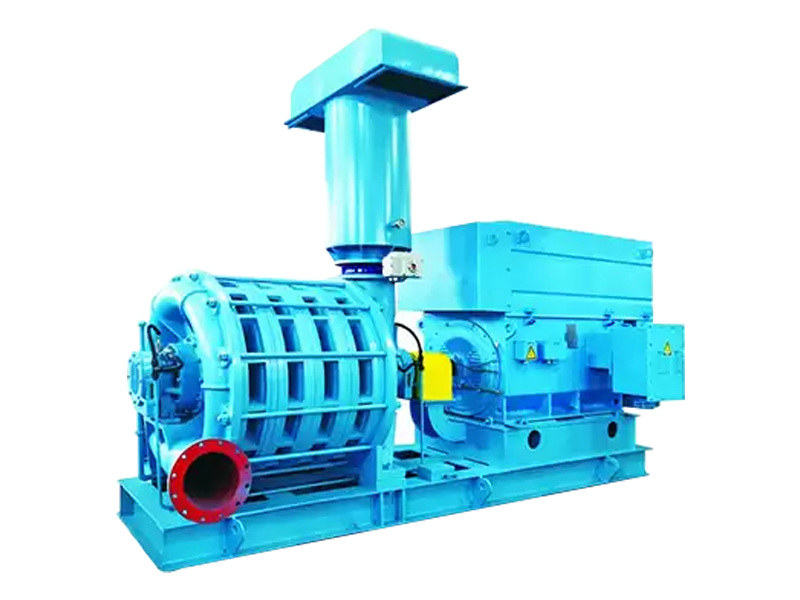

What Are Centrifugal Blowers

Centrifugal blowers are mechanical devices that move air or gas by converting rotational kinetic energy into fluid energy through a rotating impeller housed within a scroll-shaped casing. Unlike axial fans that move air parallel to the shaft, centrifugal blowers draw air in axially and discharge it radially at 90 degrees, making them ideal for applications requiring moderate to high pressure increases ranging from 1.11 to 1.20 pressure ratios.

These devices operate on the principle of centrifugal force, where air enters through the inlet near the impeller hub, gets accelerated by the rotating blades, and is flung outward into the volute casing where kinetic energy converts to static pressure. This fundamental mechanism enables centrifugal blowers to handle flow rates from 100 CFM to over 100,000 CFM while generating pressures up to 15 psi in industrial configurations.

Key Components and Working Mechanism

Impeller Design Variations

The impeller represents the heart of any centrifugal blower, and its blade configuration directly impacts performance characteristics. Three primary impeller types dominate industrial applications:

- Forward-curved blades feature 24-64 shallow blades curving in the direction of rotation, delivering high volume at lower speeds with efficiency ratings of 60-65%

- Backward-curved blades incorporate 10-16 blades angled away from rotation, achieving efficiency levels of 75-85% while providing stable operation across varying loads

- Radial blades extend straight from the hub with 6-10 blades, offering self-cleaning properties ideal for handling particulate-laden airstreams

Volute Housing and Energy Conversion

The spiral volute casing surrounding the impeller performs the critical function of converting velocity pressure into static pressure through gradual expansion. As air exits the impeller at high velocity, the expanding cross-sectional area of the volute reduces velocity while increasing pressure. Properly designed volutes can recover 40-60% of the dynamic pressure generated by the impeller, significantly impacting overall system efficiency.

| Component | Material Options | Temperature Range | Typical Application |

|---|---|---|---|

| Impeller | Aluminum, Steel, Stainless Steel | -40°F to 500°F | General ventilation |

| Housing | Carbon Steel, FRP, Coated Steel | -20°F to 400°F | HVAC systems |

| Shaft | Hardened Steel, Stainless Steel | -60°F to 600°F | High-temperature processes |

| Bearings | Ball, Roller, Sleeve | -40°F to 300°F | Continuous operation |

Industrial Applications and Performance Requirements

HVAC and Building Ventilation

Commercial HVAC systems represent the largest application segment for centrifugal blowers, where they serve as supply and return air handlers in buildings ranging from office complexes to manufacturing facilities. Forward-curved centrifugal blowers dominate this sector due to their compact size and quiet operation, typically generating 0.5 to 6 inches of water column static pressure while moving 2,000 to 50,000 CFM depending on building load requirements.

Industrial Process Applications

Process industries utilize centrifugal blowers for combustion air supply, pneumatic conveying, drying operations, and fume extraction. In combustion applications, blowers must deliver precise airflow control maintaining air-fuel ratios within ±2% to ensure complete combustion and minimize emissions. Pneumatic conveying systems for materials like cement, grain, or plastic pellets require pressure-volume characteristics that centrifugal blowers uniquely provide, operating at 3-15 psi with flow rates calculated based on material density and conveying distance.

Wastewater Treatment Systems

Municipal and industrial wastewater treatment facilities rely heavily on centrifugal blowers for aeration basins where biological treatment occurs. These applications demand continuous duty blowers capable of delivering oxygen transfer rates of 2-4 pounds O₂ per horsepower-hour at depths ranging from 12 to 30 feet. Multi-stage centrifugal blowers commonly serve this sector, with energy consumption representing 40-70% of total plant operating costs, making efficiency a critical selection criterion.

| Application | Typical Pressure (in WC) | Flow Range (CFM) | Preferred Impeller Type |

|---|---|---|---|

| HVAC Supply Air | 1-4 | 5,000-40,000 | Forward-curved |

| Dust Collection | 6-15 | 1,000-20,000 | Radial |

| Pneumatic Conveying | 40-180 | 500-5,000 | Backward-curved |

| Wastewater Aeration | 48-96 | 3,000-30,000 | Multi-stage |

| Combustion Air | 10-30 | 2,000-15,000 | Backward-curved |

Selection Criteria and Sizing Methodology

Calculating System Requirements

Proper centrifugal blower selection begins with accurate determination of required airflow and static pressure. Airflow calculations must account for the actual process requirements plus system leakage, typically adding 10-15% safety margin to theoretical values. Static pressure calculations require summing all resistance components including ductwork friction losses, filter pressure drops, coil resistance, and terminal device losses.

The total system curve plots static pressure against volumetric flow rate, and the selected blower must have a performance curve that intersects this system curve at the desired operating point. Operating between 50-80% of maximum blower capacity ensures optimal efficiency and provides turndown capability for variable load conditions.

Efficiency and Energy Considerations

Blower efficiency dramatically impacts lifecycle operating costs, particularly in continuous-duty applications. Backward-curved and backward-inclined impellers achieve peak efficiencies of 82-86% at their best efficiency point (BEP), compared to 62-68% for forward-curved designs. For a 50 HP blower operating 8,000 hours annually at $0.12/kWh, improving efficiency from 70% to 80% saves approximately $5,300 per year in energy costs.

Environmental and Operational Factors

Selection must account for ambient conditions and gas properties that affect blower performance:

- Temperature effects require density correction factors - performance decreases approximately 3.5% per 10°F increase above standard conditions

- Altitude impacts require pressure correction - capacity reduces roughly 3% per 1,000 feet elevation

- Corrosive atmospheres necessitate upgraded materials with associated cost premiums of 40-200%

- Explosive atmospheres require spark-resistant construction and potentially explosion-proof motors adding 60-120% to base equipment cost

Performance Curves and Operating Characteristics

Understanding centrifugal blower performance curves proves essential for proper application and troubleshooting. The characteristic curve plots static pressure against volumetric flow rate at constant speed, showing how pressure capability decreases as flow increases. Forward-curved blowers exhibit unstable regions where pressure rises with increasing flow, creating potential surge conditions, while backward-curved designs demonstrate stable, continuously descending curves.

Power consumption curves reveal critical differences between impeller types. Forward-curved blowers show rising horsepower with increasing flow, reaching maximum power at maximum flow - a characteristic requiring motor oversizing to prevent overload. Backward-curved impellers demonstrate non-overloading power characteristics with peak horsepower occurring at approximately 70-80% of maximum flow, allowing more economical motor selection.

Variable Speed Operation Benefits

Variable frequency drives (VFDs) enable significant energy savings by matching blower output to actual system demand. Since fan laws dictate that power varies with the cube of speed, reducing blower speed by 20% decreases power consumption by approximately 49% while maintaining 80% of full flow capacity. In variable load applications like HVAC systems where average load may be 40-60% of peak design, VFD-controlled blowers can reduce annual energy consumption by 30-50% compared to constant speed operation with damper control.

Installation and Maintenance Practices

Proper Installation Guidelines

Installation quality directly impacts blower performance, longevity, and noise levels. Foundation design must prevent vibration transmission while maintaining alignment - concrete pads should be 2-3 times the blower mass and isolated with vibration dampeners rated for 85-95% deflection efficiency. Inlet connections require straight duct runs of at least 5 duct diameters upstream to ensure uniform velocity distribution entering the impeller.

Discharge ductwork should expand gradually at angles not exceeding 15 degrees to prevent flow separation and pressure recovery losses. Flexible connectors at both inlet and outlet prevent duct vibration transmission while accommodating thermal expansion, with typical service life of 5-8 years requiring periodic replacement.

Preventive Maintenance Requirements

Systematic maintenance programs extend equipment life and maintain performance efficiency. Critical maintenance tasks include:

- Bearing lubrication every 2,000-4,000 operating hours using manufacturer-specified grease types, with excessive or insufficient lubrication causing 40% of bearing failures

- Belt tension inspection monthly on belt-driven units, maintaining manufacturer specifications typically 5-7 pounds deflection per inch of span

- Vibration monitoring quarterly using handheld analyzers with alarm limits of 0.3 in/sec velocity for warning and 0.5 in/sec for shutdown

- Impeller cleaning semi-annually in dusty environments where buildup of 1/16 inch can reduce efficiency by 5-8% and create dangerous imbalance conditions

- Motor current monitoring to detect loading changes indicating system blockage or impeller wear

Common Failure Modes and Solutions

Bearing failures account for approximately 50% of centrifugal blower problems, typically caused by inadequate lubrication, contamination, or misalignment. Implementing infrared thermography detects developing bearing issues, with temperature rises exceeding 30°F above ambient indicating imminent failure. Shaft seal leakage represents another common issue, particularly in applications handling contaminated airstreams, requiring seal replacement every 12-24 months in severe service.

Advanced Technologies and Future Trends

High-Efficiency Airfoil Designs

Modern computational fluid dynamics (CFD) enables optimization of blade profiles achieving efficiency improvements of 3-6 percentage points over conventional designs. Three-dimensional airfoil impellers feature twisted blade geometry that maintains optimal incidence angles across the blade span, reducing separation losses and extending the efficient operating range. Premium efficiency blowers meeting AMCA Class A specifications achieve 80%+ total efficiency, justifying initial cost premiums of 20-35% through energy savings realized within 2-4 years.

Integrated Control and Monitoring Systems

Smart blower systems incorporate sensors monitoring vibration, temperature, pressure, and power consumption with data transmitted to cloud-based analytics platforms. Predictive maintenance algorithms analyze operational trends identifying developing issues 2-4 weeks before failure, reducing unplanned downtime by 35-50% compared to reactive maintenance approaches. Integration with building management systems enables demand-based control optimizing performance across multiple blower installations.

Energy Recovery and Heat Reclamation

In high-pressure applications, the mechanical energy input creates significant temperature rise in the discharged air. Heat recovery systems capture this thermal energy for space heating or process preheating, recovering 60-75% of the electrical input energy in wastewater aeration applications. A 200 HP blower system can provide 400,000-500,000 BTU/hr of recoverable heat, equivalent to displacing 30-40 million BTU annually of natural gas consumption.

Cost Analysis and Economic Considerations

Lifecycle cost analysis proves essential for centrifugal blower selection since energy costs typically represent 75-85% of total ownership costs over a 15-year equipment life. A comprehensive economic evaluation includes initial equipment cost, installation expenses, energy consumption, maintenance requirements, and expected service life.

For example, comparing a standard efficiency blower at $15,000 with 72% efficiency against a premium unit at $20,000 with 82% efficiency for a 50 HP continuous duty application reveals the following annual operating costs at $0.12/kWh:

- Standard efficiency: 50 HP ÷ 0.72 × 0.746 kW/HP × 8,000 hrs × $0.12/kWh = $49,500/year

- Premium efficiency: 50 HP ÷ 0.82 × 0.746 kW/HP × 8,000 hrs × $0.12/kWh = $43,500/year

- Annual savings: $6,000 providing simple payback of 0.8 years on the $5,000 premium

This analysis demonstrates why efficiency should be weighted heavily in selection decisions, particularly for continuous or high-hour applications where premium efficiency equipment delivers rapid return on investment through reduced operating costs.

русский

русский Español

Español عربى

عربى