Wastewater treatment is a critical component of modern urban infrastructure, ensuring that communities have access to safe water while protecting natural ecosystems. Among the many processes involved in treating wastewater, aeration stands out as a key step in promoting biological treatment. At the center of this process are Roots rotary lobe blowers, a mechanical solution that efficiently supplies air to the system, supporting microbial activity and enhancing overall treatment performance.

Understanding Aeration in Wastewater Treatment

Aeration in wastewater treatment serves a primary function: supplying dissolved oxygen to microorganisms. These microorganisms, primarily bacteria, consume organic matter in the wastewater, breaking it down into simpler, less harmful substances. Without sufficient oxygen, the microbial population cannot function efficiently, leading to incomplete treatment and potential odor issues.

The aeration process can take multiple forms, including fine bubble diffused aeration, coarse bubble aeration, and surface aeration. Each method requires a reliable and continuous source of air at specific pressures and flow rates. This is where mechanical blowers, particularly Roots rotary lobe blowers, play a vital role.

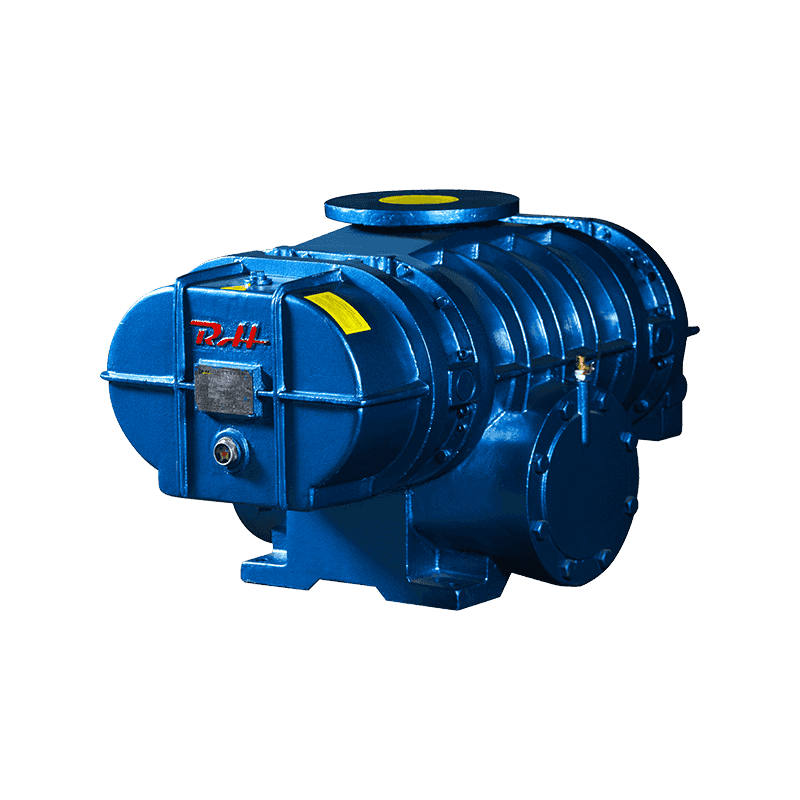

The Mechanics of Roots Rotary Lobe Blowers

Roots rotary lobe blowers are positive displacement machines, meaning they deliver a fixed volume of air for each rotation of their lobes. Unlike centrifugal blowers, which rely on velocity and kinetic energy to move air, rotary lobe blowers produce consistent airflow regardless of pressure fluctuations in the system.

The blower consists of two or more lobes rotating in opposite directions inside a casing. As the lobes turn, they trap air in pockets between the lobes and the casing, moving it from the intake to the discharge side. This simple yet effective design ensures that the blower provides steady airflow and maintains the desired oxygen levels in the aeration tanks.

Advantages of Roots Rotary Lobe Blowers in Aeration

Roots rotary lobe blowers are favored in wastewater treatment for several practical reasons. First, their design offers high reliability and durability. The lobes operate without contacting each other, reducing wear and extending the service life of the equipment. Second, they can handle a wide range of air volumes and pressures, allowing plant operators to adjust aeration rates to match varying treatment loads.

Another key advantage is energy efficiency. While aeration accounts for a significant portion of the energy consumption in a wastewater treatment plant, the precise control offered by rotary lobe blowers helps optimize energy usage. Modern blowers often include variable speed drives that adjust airflow based on real-time oxygen demand, further reducing unnecessary energy expenditure.

Maintenance is also relatively straightforward. Routine checks of bearings, seals, and lubricants are typically sufficient to keep the blower in good working condition. Because Roots blowers are mechanically simple and robust, unplanned downtime is minimized, ensuring that the aeration process remains uninterrupted.

Integration with Aeration Systems

In practice, Roots rotary lobe blowers are integrated with diffused aeration systems through a network of pipes and diffusers. The blower generates pressurized air, which travels through piping and is evenly distributed across the aeration tank via fine bubble diffusers. Fine bubbles provide greater oxygen transfer efficiency compared to coarse bubbles due to increased surface area, which improves microbial activity and treatment effectiveness.

The ability of Roots blowers to maintain constant pressure is crucial in this setup. Fluctuating airflow can cause uneven oxygen distribution, creating zones of low dissolved oxygen where microbial activity is hindered. By delivering consistent air, the blower ensures uniform treatment across the entire tank.

Monitoring and Control

Modern wastewater treatment plants often employ automated monitoring systems to maintain optimal aeration conditions. Sensors measure dissolved oxygen levels, flow rates, and tank parameters, providing real-time feedback to the blower control system. When oxygen levels drop, the blower can increase airflow, and when oxygen demand decreases, it can reduce output, saving energy while maintaining effective treatment.

Variable speed drives and blowers with integrated control systems also improve operational flexibility. Plants can adapt to daily fluctuations in wastewater volume or seasonal changes in organic load, ensuring compliance with environmental regulations without excessive energy consumption.

Challenges and Considerations

While Roots rotary lobe blowers are reliable and efficient, they require proper selection, installation, and maintenance to perform optimally. Oversizing a blower can lead to energy waste, while undersizing may result in insufficient aeration and suboptimal treatment. Engineers must carefully calculate the required airflow and pressure based on tank volume, oxygen transfer efficiency, and peak organic load.

Noise is another consideration. Blowers can generate high decibel levels, particularly at high speeds. Effective sound enclosures, vibration isolation, and strategic placement within the plant can mitigate noise impact, improving the working environment for operators.

Finally, lubrication and bearing maintenance are critical for long-term operation. While the mechanical simplicity of the design minimizes wear, neglecting lubrication schedules can lead to premature failures and costly downtime.

Innovations and Future Directions

Recent advancements in blower technology have focused on enhancing energy efficiency and operational control. Variable speed blowers, improved materials, and precision-engineered rotors contribute to higher performance with lower energy consumption. In addition, integration with smart plant management systems allows for predictive maintenance, reducing unexpected failures and extending equipment lifespan.

Research is also ongoing into optimizing aeration strategies, including intermittent aeration and fine-tuning airflow patterns to match microbial requirements more precisely. As environmental standards become stricter, these innovations will support sustainable wastewater treatment while minimizing operational costs.

Conclusion

Roots rotary lobe blowers are an indispensable component of modern wastewater treatment, providing the reliable and consistent airflow needed for effective aeration. Their mechanical simplicity, durability, and adaptability make them well-suited to the demanding environment of treatment plants. By ensuring optimal oxygen transfer, these blowers support microbial activity, enhance treatment efficiency, and contribute to the overall sustainability of wastewater management systems.

As treatment technologies evolve and energy efficiency becomes increasingly important, Roots rotary lobe blowers will continue to play a central role in keeping the heart of the plant—its aeration system—running smoothly. Through careful design, maintenance, and integration, these blowers help wastewater treatment plants meet environmental goals while providing communities with safe and clean water.

русский

русский Español

Español عربى

عربى