In the relentless world of industrial operations, equipment failure isn’t merely an inconvenience—it’s a cost. A pause in productivity, a spike in maintenance expenses, and a dent in operational integrity. Among the many workhorses of industry, the Roots blower stands as a stalwart provider of air and gas movement. But when corrosive environments enter the equation, conventional models quickly falter. This is where the anti-corrosion Roots blower steps in—engineered not just for performance, but for endurance.

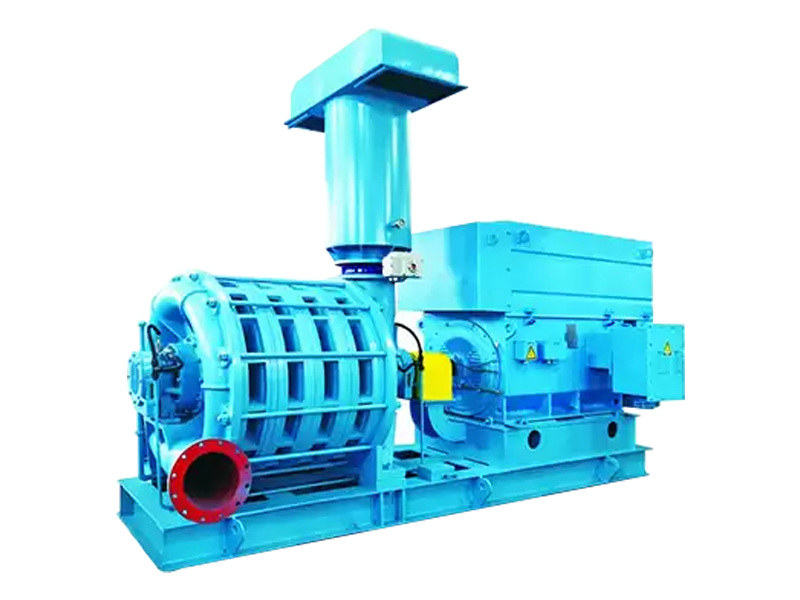

At its core, a Roots blower functions through the positive displacement of air, utilizing twin rotors to push a consistent stream of gas or air through a system. It’s a simple mechanism, but in corrosive settings—chemical plants, wastewater treatment facilities, marine applications—that simplicity must be armored with innovation. The anti-corrosion variant delivers precisely that: uncompromising reliability under the harshest conditions.

What distinguishes an anti-corrosion Roots blower from its standard counterpart is its meticulous construction. Every component exposed to corrosive agents is fortified—through advanced coating technologies, the use of high-grade stainless steel, or non-metallic liners. These enhancements prevent degradation caused by acidic vapors, salty air, and aggressive chemical compounds. It’s a shield, not a compromise.

The value proposition is unmistakable. Downtime is minimized. Maintenance intervals are stretched. Operational efficiency is preserved. Where traditional blowers corrode and collapse, the anti-corrosion design sustains performance with resolute consistency. That resilience translates into tangible ROI: fewer replacements, lower total cost of ownership, and uninterrupted throughput.

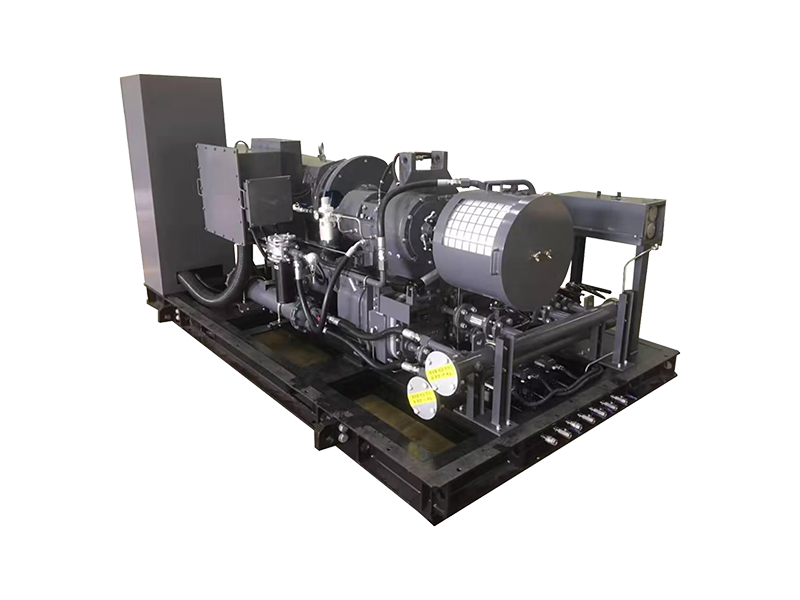

Moreover, modern anti-corrosion Roots blowers are far from brute-force machines. They are refined, often featuring precision-balanced rotors, noise-reduction designs, and energy-efficient drive systems. Despite their armored build, they maintain the finesse required for sensitive applications. In environments where corrosive gases are present but where vibration or noise must be tightly controlled—such as laboratories or semiconductor manufacturing—these blowers deliver with elegant precision.

Selecting the right anti-corrosion Roots blower, however, demands more than an off-the-shelf purchase. It requires a tailored approach. Factors such as the nature of the corrosive agents, required flow rates, pressure demands, and environmental conditions all influence the optimal configuration. Partnering with a knowledgeable supplier is critical—one that understands not only the engineering, but the nuance of your specific application.

In an industrial age where environmental conditions are increasingly unpredictable and raw materials more aggressive, resistance to corrosion is no longer optional—it’s essential. The anti-corrosion Roots blower answers this challenge not as a niche product, but as a necessity for forward-thinking operations.

To invest in one is to invest in operational continuity, in the integrity of your process, and in the long-term strength of your infrastructure. When corrosion threatens to eat away at the foundations of performance, the solution isn’t to slow down—it’s to stand firm with technology built to endure.

русский

русский Español

Español عربى

عربى